Often for filing, drilling or sawing, vises are inconvenient, bench top is in the way or mid-air holding is unstable. This is particularly true with flat pieces. Jewelers and craftsmen solved this problem by adding bench extensions or blocks, many of which were used occasionally, clampable and specialized. They ran from simple blocks or bars to complicated shapes. Some are used to mount power tools.

A very simple, clamp-on version has a vee notch and round hole to permit use of frame or jeweler's saws on flat sheets, while hand holding flat sheets on surface. Use can be expanded to other similar jobs as filing and sanding.

Note: Adjust brightness and contrast for optimum viewing.

Simple wooden bench block.

Clamp is recessed to provide completely flat surface.

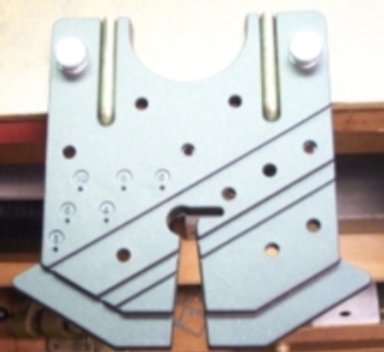

Designed for model ship builders, Amati offers, the "Planet", a more sophisticated version, which in addition to the VEE and hole has several useful aids added. Three grooves can hold rods or other parts for cutting or shaping. Two grooved pins can be placed in various holes to serve as back-stops for workpieces . The stepped front can backup strips for shaping, drilling etc.. Six holes serve as drill bit guides in top with concentric holes in bottom align 3 mm to 10 mm dowels or rods for center drilling ends. The pin holes accept small accessory clamps to hold odd work. Recessed clamps provide a flat surface.

Note: Adjust brightness and contrast for optimum viewing.

Amati complex bench extension.

BACK TO TOOLS INDEX

BACK TO METHODS

HOME