Saws are designed with chisel teeth that cut only in one direction and like files should be lifted on the return stroke to avoid dulling teeth. Although not all are always given there are a few dimensions that may be critical. The number of teeth per inch (tpi) determines how deep and fast each pass is. Larger teeth will cut softer materials faster without clogging. Smaller teeth are required for harder materials to reduce tooth breakage. On thinner work, they prevent spanning the thickness and tearing sheet. They also produce a cleaner cut. Rarely given for small blades is the offset of the teeth, which is required to widen the kerf to clear the blade to prevent heating and jamming. The thickness should be measure across this offset and not across the blade. The width of the blade determine it rigidity, but limits the radius of cut. Normally length is only critical in cases where both ends are held by a frame.

It should be pointed out that in splicing , The thinnest, smoothest and straightest cut should be made; since even a .010" kerf is about 7/8" in HO. Particularly at sharper edges, the usual starting method is to start the kerf with a light back cut, else blade may wander and tear edge.

Modelling sized saws come in several forms.

Interchangeable knife blade types are useful for some sizing jobs and particularly in enlarging holes for windows and doors. Particularly with thinner blades, cutting part of the cycle should be pulled to avoid flexing the blade, which would widen kerf or possibly bend blade.

Note: Adjust brightness and contrast for optimum viewing.

SAW BLADES

Fine point. Several thicknesses and tpi. Pull.

#13. Pull.

#15 keyhole. Use #2 handle. Push.

Note: Teeth on bottom edge.

In some cases it may be preferable and possible to clamp saber saw blades or short stubs of broken jeweler's saw blades in some knife handles.

Razor saws or more correctly , rigid backed, are commonly used for longer straight cuts. With narrower blade, they can be quite thin. Frequently they are used with miter boxes to guide both horizontal and vertical angles. However tooth offset permits error, since the kerf is wide enough to clear the teeth and the guiding is done on the blade. Wear in the kerf is quite rapid, due to tooth contact. Resistance to this seems to increase from wood, through aluminum to plastic. Acetal plastic should be better. Handles and stiffening methods vary. On Xacto types and Atlas it is permanently attached to the blade, while Zona uses slot in the the handle with flat changeable blades. They also offer the widest selection of types, sizes and blade thicknesses. Replacing just the blade is far more economical.

Note: Adjust brightness and contrast for optimum viewing.

RAZOR SAWS

Zona large.

Xacto wide, coarse. Angle is usually more convenient

Note: Adjust brightness and contrast for optimum viewing.

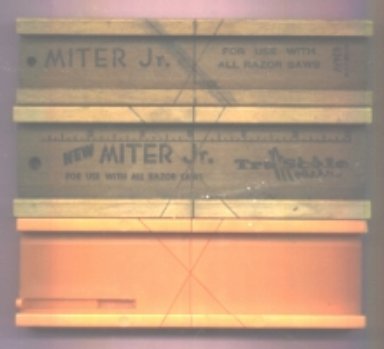

MITER BOXES

Old Ayers wood.

Old True-Scale wood.

Zona plastic with adjustable stop.

Note: Adjust brightness and contrast for optimum viewing.

Xacto deep aluminum.

For larger scales and dollhouse work.

Jeweler's saw frames can mount the finest blades under tension to reduce wandering from bending. The throat provides enough clearance for most projects. On some the direction of cut with respect to frame can be changed by turning clamps, but twisting blade should be avoided.

Due to jewelry processing requirements, a very wide selection of all parameters is available. Some blades have piercing teeth for bone and (now illegal) ivory work. Others have spiral teeth which cut in any direction. They are usually sold in a wire wrapped bundle of 12. The biggest secrets to use are: the blade should be as tight as possible; to distribute wear, use as much of the blade as possible and progress should be slow. Although blades have quite a bit of spring, they can snap. A pull cutting stroke is recommended to reduce bending.

When sawing inside a hole, the blade must be passed through it and then mounted on the frame. After sawing is finished, the blade must be loosened to remove it.

Note: Adjust brightness and contrast for optimum viewing.

JEWELER'S SAW

To support the work piece and permit unrestrained pulling movement of the saw and hand, a very simple wooden, 2 1/2" X 7 1/2" ,sawing bench extension is clamped to the edge. Clamp is recessed to eliminate interference with work piece. A Vee cut provides easy access to a 3/4" circular hole at the vertex, which permits sawing without cutting the support.

Note: Adjust brightness and contrast for optimum viewing.

SAWING EXTENSION>

Before the development of power reciprocating saws, hack saw were commonly used to cut bar stock as hard as cold rolled steel by hand. They can still find use in hard to fit places. Stretched on a frame they resemble large jeweler's saws and can perform similar functions on a heavier scale. Although thicker and wider, blades are selected the same way. Normally the cutting stroke is pushed. A single ended handle version is very handy in tight spaces. The exposed length is adjustable.

Note: Adjust brightness and contrast for optimum viewing.

HACK SAWS.

Frame type with thumbwheel tightening and finger guard..

Single ended.

For cutting electrical outlet holes and other small rough sawing, where a powered saber saw will not fit, a self starting keyhole saw is very handy and comfortable to use. Larger sizes are available.

Note: Adjust brightness and contrast for optimum viewing.

KEYHOLE SAW

Unless some physical exercise is needed, larger and heavier sawing is best left to power tools.

BACK TO CUTTING

BACK TO TOOLS INDEX