A large percentage of projects are one shots with no repeats. There are many cases where marking on the finished surface of a model is undesirable, but positions must be located. Many surfaces are curved or contoured, making measurements difficult. Some require bending, twisting or shaping. Reworking metals and stiffer materials can be time consuming and almost impossible in some cases. Paper, thin card stock or thin metal sheet can be used to make inexpensive, expendable templates or patterns for trial and error.

American Beauty Line passenger cars included a paper template which was taped to roof to locate details.

Note: Adjust brightness and contrast for optimum viewing.

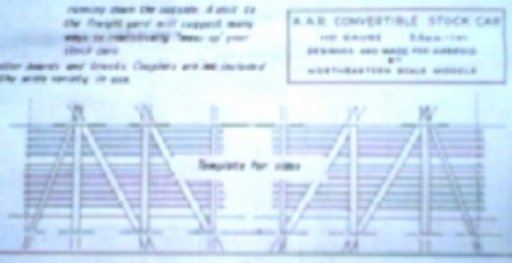

North Eastern instruction sheets often had cutting and shaping guide lines printed right on the scale drawings. Example is the Convertible Stock Car.

Note: Adjust brightness and contrast for optimum viewing.

T. ALIGNMENT AND CUTTING TEMPLATE.

B. CAR SIDE.

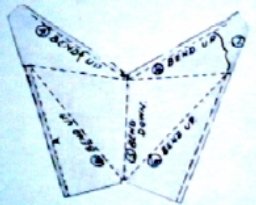

North Eastern included a paper bending template for the aluminum sheet plow on their winged snow plow.

Note: Adjust brightness and contrast for optimum viewing.

L. TEMPLATE BEFORE CUTOUT AND BENDING.

R. BENT TEMPLATE AND PLOW PRIOR TO FINAL TRIMMING.

Making conical roofs for silos or water tanks can be quite involved in trigonometry and layout to set the pie shaped cutout angle required. but a paper mockup is easy to make and try, with only one measurement.

Note: Adjust brightness and contrast for optimum viewing.

Take the sloped radius from the plans and draw and cut a circular disk from thin card stock. Cut a radius line, apply temporary stick or similar glue along one edge and overlap the edges to make a cone. Try it for fit on cylinder and adjust. Mark edge and draw radius through mark, Cut and remove pie wedge for butt splice template.

¬DJUSTABLE

In many cases, it is neccessary to copy shapes, contours or forms to make duplicate copies. Adjutable template formers can help by conforming to pattern shape.

One type consists of a 1" stack of 2" X 5" plastic sheets sandwitched between two blocks of wood. Two screws with wing nuts loosen for setting and tighten for securing.

Note: Adjust brightness and contrast for optimum viewing.

SHEET DUPLICATOR

Another type uses thin metal rods held by sprung friction with 5 7/5" usable length.

Note: Adjust brightness and contrast for optimum viewing.

PIN DUPLICATOR

BACK TO TEMPLATES