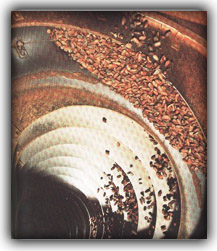

At the chocolate factory, the cocoa beans

are cleaned, roasted and shelled. The roasting fills the sir with

chocolate's mouthwatering aroma. The beans are broken into larger

pieces called nibs and then these are grounded, producing rich brown liquid

or paste called "chocolate liquor” (although it has no alcoholic content).

This liquor is the main ingredient for all chocolate

| products. Some of the liquor id hardened into moulds to

form baking (bitter) chocolate but most is pressed to extract the cocoa

butter. The resulting block, once the cocoa butter has been removed,

is called "dress cake”. This is dried and sifted to make cocoa powder. |

|

These three products- chocolate liquor, cocoa

powder and cocoa butter- are combined to make all the different kinds of

chocolate.

To make milk chocolate, the chocolate liquor

is added to fluid or powdered milk sugar. If cocoa butter and sugar

only are used, with no chocolate liquor, white chocolate will result.

Cocoa butter plus chocolate liquor and sugar makes the familiar sweet (eating)

chocolate. If vegetable fat is substituted for cocoa butter, the

resulting baker's or compound chocolate cannot be legally sold as chocolate

in most countries.

|

To make milk chocolate,

the chocolate liquor is added to fluid or powdered milk sugar. If

cocoa butter and sugar only are used, with no chocolate liquor, white chocolate

will result. Cocoa butter plus chocolate liquor and sugar makes the

familiar sweet (eating) chocolate. If vegetable fat is substituted

for cocoa butter, the resulting baker's or compound chocolate cannot be

legally sold as chocolate in most countries. The mixtures are blended,

spices and flavorings may be added, then the chocolate |

| undergoes a long stirring or "conching”

period to make it smooth and creamy. After this, it is moulded into

blocks and bars, wrapped and shipped to bakeries where it is used as an

ingredient in cakes and biscuits, or sent straight to confectioneries. |

|

Finally the dried seeds are ready for packing

shipping. Then the manufacturer takes over. Since chocolate

seeds from various countries and from different plantations and different

trees do not all taste alike, the chocolate manufacturer will probably

blend several different types. And manufacturing methods differ from

one factory to another. Timing, temperatures, proportions of ingredients,

and processing are all extremely closely guarded secrets.

|

Once in the factory, each step is carefully

controlled under the most sanitary conditions. First the seeds are

fumigated and stored in a clean, cool, airy location where they cannot

absorb any odors. Next they are sieved and cleaned by a machine that

removes any dried pulp, pieces of pod, etc., that may have remained.

Then they are weighed and blended according to sizes. Next they are roasted

in large rotary cylinders at a temperature of 25C to 35C for thirty minutes

to two hours, depending |

on the seeds and the manufacturer's formula. At this stage,

for the first time, they begin to develop a "chocolate” flavor and aroma.

After roasting and cooling, the seeds are shelled,

leaving the meat, which is called "nibs”. The nibs contain an average

of 50% to 54% cocoa butter, which is a natural vegetable fat. The

next step is to crush the seeds between large grinding stones or heavy

steel disks. This process, called conching, generates enough heat

to liquefy the cocoa butter, most of which is removed, leaving a thick,

dark paste which is called the chocolate "liquor.” When this liquor

is poured into molds and solidified, it is unsweetened chocolate.

If still more of the cocoa butter is removed, it is cocoa powder.

|