We have successfully grown more than 10 typies of Perovskite

Oxide thin |

|

Homepage-->Research

Atomic engineering of complex oxide thin

film and superlattice by Laser MBE

[Research] [Experience] [Enterprise]

[Interests][Publication]

| 2001,11-now | 1. Optical (sub-minimeter microwave) study of high-Tc superconductors |

| 2. Optical Study of YBCO/LaCaMnO heterostructures and superlattices |

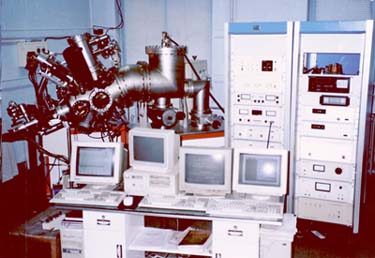

| 1997-2001 | 1. Laser-MBE growth of Complex Oxide thin films and superlattice |

| 2. Surface optical diagnosis and SHG study | |

| 3. Monte Carlo Simulation of the growth kinetics | |

| 4. Oxide heterojunction and High-K dielectric oxide thin film |

1.Laser-MBE growth of Complex Oxide thin films and superlattice

We have successfully grown more than 10 typies of Perovskite

Oxide thin |

|

¡¡

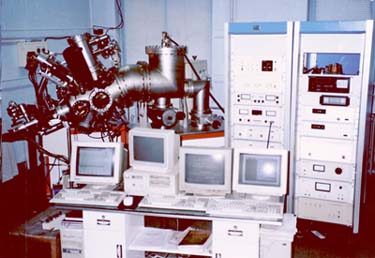

Figure 1 shows an atomic force microscopy (AFM) image of BaTiO3 thin film. The surface root means square roughness is 0.055nm.The height profile suggests that the range is within atomic height 0.2nm. |

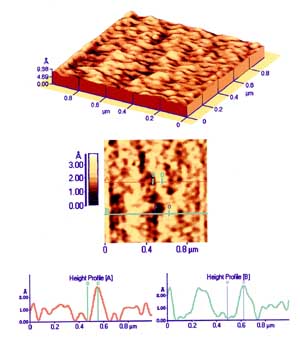

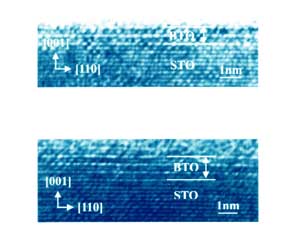

Figure 2 shows a high resolution TEM picture of BaTiO3/SrTiO3 (BTO/STO) superlattice. The thickness of BTO and STO is 20 and 10 unit-cell. It can be clearly counted from this picture. |

||||||||||||||||||||||||||||||||||||

|

<=== Figure

3 Figure 3 shows high resolution TEM picture of ultro thin BaTiO3 thin film on STO substrate. The thickness of BTO is 2 and 3 unit-cell, respectively. |

||||||||||||||||||||||||||||||||||||

| SHG

study of BTO/STO superlattice Paper-Link (pdf)Phys. Rev. B, 60, 1697 Table 1. SHG coefficients of various BTO/STO superlattices with various stacking periodicities

|

The

second-order nonlinear optical susceptibility of [BaTiO3(2 unit cells)/SrTiO3(2

unit cells)]50 Superlattice, d33=156.5pm/V, is 22 times larger than that of bulk BaTiO3

single crystal , d33=6.8pm/V. |

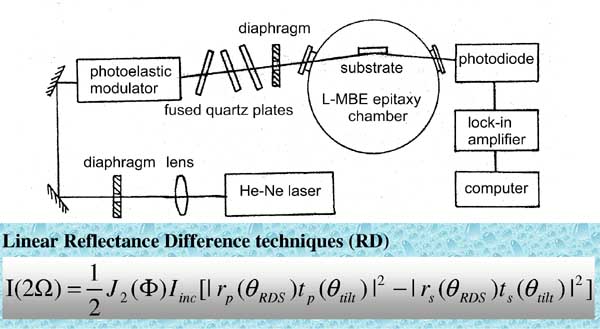

2.Surface

optical diagnosis

We adapte an optical oblique-incidence

reflectivity difference (OIRD) device

to the growth chamber of Laser MBE for real-time diagnosis of the growing

surface.[PRB-vol

(57)-page 2514,1998] ;

[PRB-vol

(61)-Page 10404,2000]

Figure 4 Sketch of the optical setup of the oblique-incidence reflectance difference (OIRD) measurement. PEM: photoelastic modulator. QW: fused quartz parallel plate. PD: biased silicon photodiode. |

|

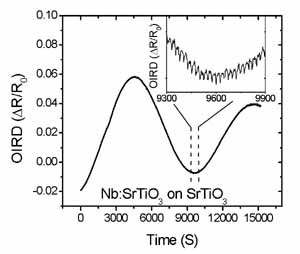

Figure 5 Interference oscillations and monolayer oscillations (the inset) obtained by OIRD during the heteroepitaxy of Nb-doped SrTiO3 on SrTiO3 (100). |

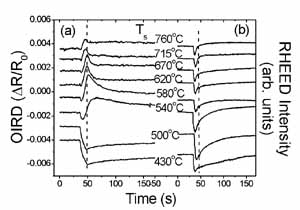

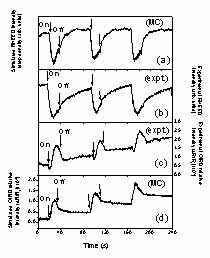

Figure 6 Simultaneously measured OIRD signals (a) and RHEED intensity signals (b) for the growth of one monolayer SrTiO3 as a function of the substrate temperature Ts. The dashed lines indicate the interruption of growth. For more==> |

3. Monte

Carlo Simulation of the growth kinetics

We use Monte Carlo simulation to study the

optical (OIRD) signal and

RHEED response.

|

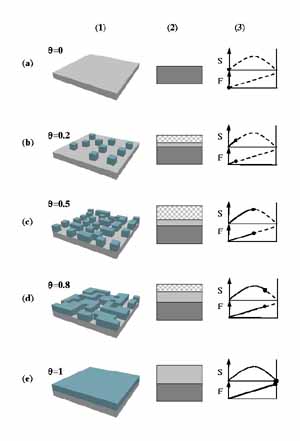

<==Figure 7. we treat the topmost incomplete layer as two parts, a surface layer with an average dielectric constant and a film layer below that with the dielectric constant of the bulk film. The variations of the surface layer height during layer-by-layer growth are schematically illustrated in (a)-(e). Column ¡°1¡± shows the schematic surface morphology for different surface coverage q , column ¡°2¡± shows the corresponding layer structure in our model. The variations of the surface layer height (S) and the film thickness (F) are shown in column ¡°3¡±. The dashed curve in column ¡°3¡± shows the trend of the variations and the solid dot at the end of the solid curve indicates the current value corresponding to the surface morphology shown in column ¡°1¡±. At the beginning of the deposition on smooth surface, the surface layer height increases as a result of surface roughening (Fig. 7a-7b) and reaches a maximum at about half layer coverage (c). During the subsequence growth, the coalescence of 2D-islands which leads to surface smoothening results in corresponding decrease of the height of the surface layer (d-e). The thickness of the bulk film increases continuously throughout the deposition process. |

Figure 8==> Fresnel¡¯s equations for a multi-layer stack are

used to calculate the reflectivity of s- and p-polarization. |

|