Physical Implementation

Now that all the specifications and components have been described along with the electrical schematics, how is all this supposed to come together in a helmet? As previously said, we have chosen not to design the helmet itself, but to add on to an existing helmet. This helmet cannot be just any old helmet though. The helmet must be appropriate to the chosen activity and it must meet safety standards. If one wears a toy hard hat to go extreme mountain-biking, he or she might as well call the ambulance before hand.

We, the gamma group have chosen to implement our force-sensitive location device onto a bicycle helmet. This is because in the west coast, mountain biking is a very popular sport and helmets bylaws in certain cities in the region requires all bikers to wear protective head gear. To satisfy the quality requirement we have set, we have decided to use a helmet of Snell B-95 standards. Snell B-95 is a bicycle helmet standard set by the Snell Memorial Foundation and is internationally recognized. Also, Snell B-95 standards exceed the Consumer Product Safety Commission standards that are required in all bicycle helmets sold in the United States (http://www.smf.org). Preferably, we would want a helmet that even exceeds the Snell B-95 standards because the structural integrity of the helmet will be very slightly affected by the integration of the sensors.

First, a small divot the diameter and depth of the force sensor will be routed into the inner shell of the helmet. Then, another small channel from the divot will be routed to fit the "tail" of the force sensor. The force sensor is then planted into the divot made with the force sensing side up (Refer to fig. P-1). This is then secured to the helmet by adhesives and then taped with industrial strength tape. The relatively small size of the divots needed to embed the impact sensors will not affect the performance of the helmet.

Since the comfort foam in the helmet provides a small clearance of approximately 1-2 cm, we are able to secure the wires from the force sensors simply by adhesives and tapes. No further channels will have to be routed into the helmet and therefore no further impact absorption will be sacrificed.

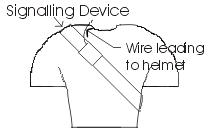

The wires will all be directed to join near the back of the helmet for minimum obstruction to the user. These wires will then lead down the voltage comparator and signaling device (fig P-2). The signaling device is attached via adhesives to a diagonal chest band (fig. P-3) similar to the style used in the popular new chest style backpacks of today's youth. The signaling device can also be put into the user's bag. Gamma group believes that the diagonal chest strap design will be the least intrusive, most portable, and most ergonomic design.