Good Connector shall has an Approval Standards, such as UL, CSA, ISO.

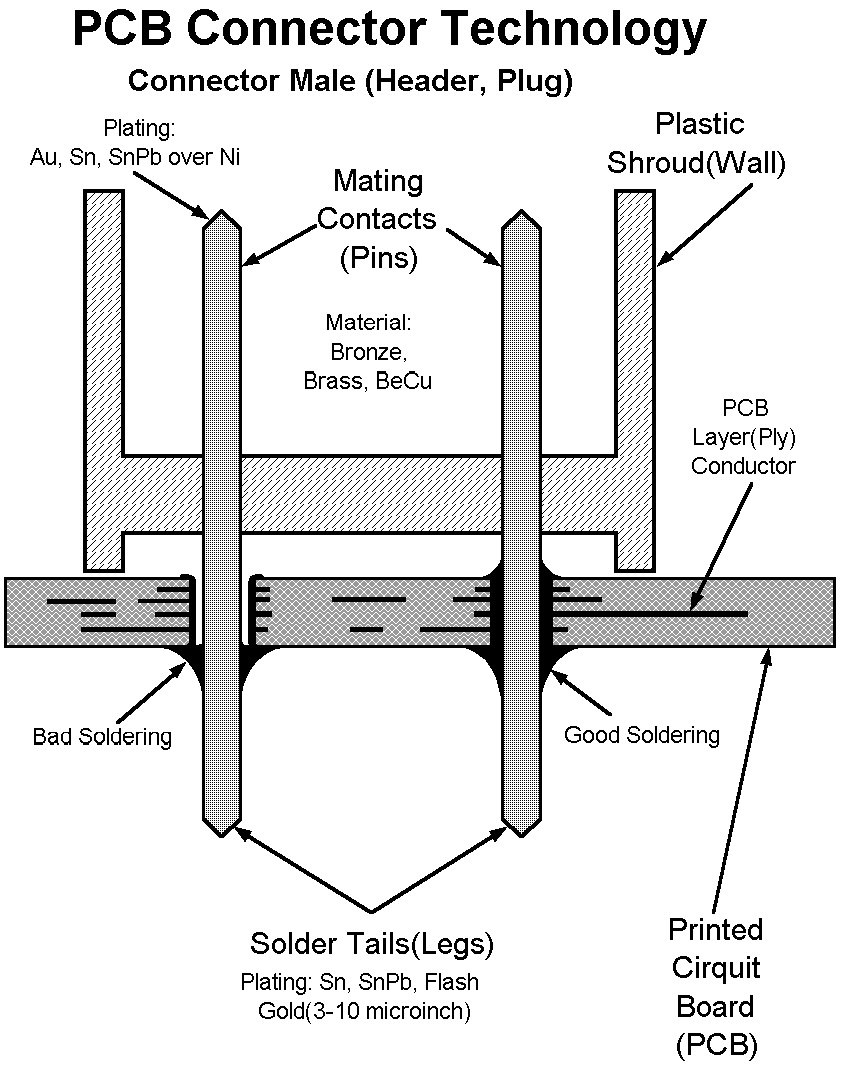

Plating

- General:

- A Good Contact shall be plated AFTER Raw Metal Strip Cutting,

and shall has All Surfaces Plated. CHECK IT!

- The Plating Thickness is define a Number of Mating Cycles.

The Plating Thickness be measured by the Thickness of External Plating Layer,

but Internal Layers Thicknesses are significant for Working Life Time (Include Stock Shelf Life).

- The Porosity - quality of Plating is a vitaly for Working Life Time.

The Porosity is not listed in a Connector Specifications,

but a Good Manufacturer make a Plating with Low Porosity.

- Gold Plated Contact non Allowed with Tin Plated and Opposite.

- Structure of Plating:

Gold(Au) or Palladium(Pd) or Tin (Sn) or Tin-Lead (SnPb - better for Long-Life) over Nickel(Ni) over Base Metal(Brass or ?).

- Mating Contact Plating is defined by a System and Connection Application.

Application Simple Toy Home/Desktop Equipment Communication Equipment Military or Test Equipment Mating Contact Plating Flash Gold(5-10 Microinch Gold) or Tin 15-30 Microinch Gold over Ni. 30 Microinch Gold over 50-80 Microinch Ni. 50-100 Microinch Gold over 80-150 Microinch Ni. Number of MatingCycles 20-50 100-200 250 500 Working LifeTime up to 3 5-7 10-20 "Forever" Performance Level per DIN 41612 part 5 - 3 2 1

- PCB or Wire mounting Tail (Leg) Plating mostly is a Tin (Sn) or Tin-Lead (SnPb), Thickness 20-150 Microinch.

- Metal Shell and Accessories Plating mostly is a Yellow Crom (Cr) or Nickel(Ni)

or Tin (Sn) or Tin-Lead (SnPb), Thickness 20-150 Microinch.

- 1 Micrometer ~= 40 Microinch

- 1 Microinch ~= 0.025 Micrometer

- PCB or Wire mounting Tail (Leg) Plating mostly is a Tin (Sn) or Tin-Lead (SnPb), Thickness 20-150 Microinch.

Back

HOME

Mail

Conn. Families Tree

Copyright © 5761/2000 Nothing reserved.