The following

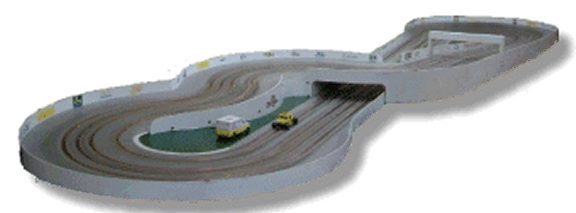

are pictures of the different building stages of my road course track. The

track is constructed of 1/2-inch MDF built on a table constructed of 2x4's

and topped with 1/2-inch MDF. The table surface measures 4 feet x 16 feet.

I put the table on casters so that it may be moved if necessary. The track

surface was cut from two 4x8 sheets of MDF with a small piece (the light colored

piece under the overpass) linking the two big sections together.

I designed the

track on the computer using Turbo Cad. This eliminated a lot of trial and

error fitting and mistakes. I could determine each turn radius, elevations,

and bank construction.

I

first routed the outside lane with a tramel and straight edge. I then used an

offset router jig I made to route the remaining slots by riding in the previous

slot. The

banked turn has a 10-degree bank which allows a little more speed from the relatively

short track. But at the same time, you still have to "drive" through

the turn. The other end of the track has a flat turn going into the S's. I have

6-inch aprons on most of the turns to leave plenty of room for the larger cars.

The

slots are 1/8-inch wide, 5/16-inch deep, and I used 1.5 mil 3/16-inch wide copper

tape for power. The MDF is painted with three coats of light grey satin latex

garage floor enamel. A 12-volt battery powers the track through two power taps.

The track walls are

made from 1/8-inch tile board with the tile side facing the track. The back

side is painted white.

I

tried to cover as little of the track as possible with the overpass by crossing

at a 90-degree angle. The clearance is 3 1/2 inches to allow my taller cars

to pass through.

Each

of the four drivers stations is

wired for alligator clip connections. Each panel has brakes,

a reverse switch, a kill switch, and a power indicator light.

The reverse

switch lets you basically run a different track in the opposite direction. The

kill switch eliminates hectic marshalling problems.

I

am using Lap Timer 2000 for a

timing system. I built the light bar over the track to trigger the Radio Shack

infrared photo transistors in the track as the cars pass over. I am using this

system with an old computer I had sitting around. The system works flawlessly!

The whole system cost less than $20 (not counting the computer) and very simple

to construct. I

tried using LED's in the light bar with little success. I switched to two 25-watt

(to cut down on heat) long bulbs. They produce plenty of light to trigger photo

transistors. The light bar itself is constructed of MDF and 1/4-inch plywood.

The supports are notched to just slide over the walls on either side.

You'll

notice that my lane spacings are not the same for all 4 lanes. Three of the

lanes are spaced 2-inches apart for HO scale cars using Slide Guides.

I can use the

two outside lanes and center lane, spaced 4-inches apart, for 1/32 and 1/24

cars. This way I can run all scales of cars and still have door-banging action.

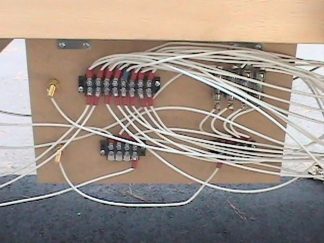

Track

wiring is attached to a hinged panel that swings down from under the track for

access. Each lane is fused with a 5-amp fuse. The 12-volt battery is alligator-clipped

to the two brass screws on the left.

The

computer is mounted under the track in the center. The wall panel over the keyboard

is removeable to have access to the power taps and the infrared photo transistors.

The name says it

all! The track is short but a blast to drive. Thanks for taking the time to

view my efforts!