"WHERE H.O. IS KING!"

THE TRACK T-JETS AFX PROJECT CARS HOME

|

|

"WHERE H.O. IS KING!" THE TRACK T-JETS AFX PROJECT CARS HOME |

|

|

|

|

There are two kinds of supports used for the elevated sections of the new ThunderRoad Speedway. Shown at left is one of the under table supports, which is screwed to the table cross pieces. Notice also the pre-drilled wiring holes, and the wing nut and bolt used to join the two separate tables. |

|

The second type of elevation support is cut to sit on top of the table surface and is screwed through a wing or foot into the table top. This is useful in areas that need support but do not have a properly located cross brace beneath. This particular brace is at the point where the elevated track passes over the lower track. |

|

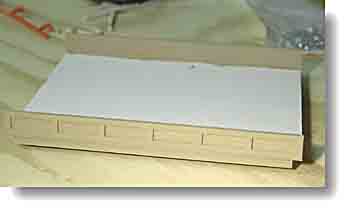

The bridge for the overpass was constructed completely of Evergreen Styrene products. The floor was made of .060" sheets. The under bridge construction shown at the left is of "I" beam pieces, with the cross pieces laminated from two thicknesses of .060" scrap. |

|

The sides of the bridge were constructed of sheet styrene and styrene channel to form a concrete-like bridge design. The bridge is 2" wider than the track it will carry, to left ample room for shoulders, since it will be very close to curves at both ends of the bridge. |

|

The bridge supports that will support the bridge structure were made from 1" thick blue styrofoam insulation board. Three pieces were used for each support, with the base and top cut at a 10º angle so they would lean backward into the banks. The face was scored with a file to simulate separate concrete pieces, and the assembly painted with Polly-S Aged Concrete railroad colors. |

|

|

MORE OF THE CONSTRUCTION OF THE NEW THUNDERROAD. |

|

|

|

|

THANKS FOR COMING -- COME BACK SOON! |

|

Revised, January 8, 2001 |