This is information regarding reloading with 22/30 sabots ...

If you haven't already done so, you may want to read about sabots ...

These sabots make it possible to shoot .224 caliber bullets in your .308 caliber rifle. The advantage of using sabots is that you get increased muzzle velocity, which translates (initially, at least) to a flatter trajectory. Basically, you can turn your .30 caliber deer or target rifle into a varmint gun, assuming you get good accuracy from your loads. The bullet is not deformed by the rifling, helping the bullet's flight by maintaining BC. Expect about 3800 - 4000 fps from your .308 Winchester, and about 4200+ fps from your .30-06 Springfield. At this point in time, I'm going to have to trust the load data and the POWLEY calculator where velocity is concerned. I tried measuring velocy with my chronograph, but got very erratic (estreme spread = 368 fps, SD = 118) and low velocity readings. I also managed to hit my chronograph with an errant sabot (which caused only cosmetic damage). (I know my chronograph is OK, because my standard 168 grain loads performed well.) E. Arthur Brown Co. recommends that you do NOT use sabots in rifles with muzzle brakes. I think the nylon sabot would end up clogging the brake.

Notice that I said increased muzzle velocity. Bullet trajectory, velocity (and energy) at range must be a factor when varminting. These can be determined by using an external ballistics computer.

I've read that another advantage is that they are cheaper to shoot. I don't agree, because while good .308 caliber bullets may cost $18-20 per hundred vs. $10-12 per hundred for .224 caliber bullets, the sabots cost anywhere from $6-10 per hundred ($4 per thousand if you buy bulk), yeilding a cost of $14-22 per hundred. Also, the powder charges are pretty much the same. In my book, conventional vs. sabot rounds are pretty much even from a cost standpoint, with a slight edge going to the sabot rounds.

This is a .308 Win. case loaded with a sabot/Sierra 55 grain HP Match bullet. The two unloaded bullets are molyed and plain Sierra 55 grain HP Match bullets.

This is basically the same shot as above (a little out of focus - sorry) but with an additional bullet seated in the sabot ready for loading.

This is a comparison of the .308 Sierra 168 grain HPBT Matchking and the .224 Sierra 55 grain HP Match bullets (both moly treated). At about 1/3 the mass, it's easy to see why the sabot round is so darned fast!

The sabots I use weigh 6 grains. Weigh yours when you get them. This weight should be added to your bullet weight (yeilding total projectile weight) if you calculate your own powder charge (eg. using a powley calculator). Only the bullet weight should be considered when calculating trajectory, velocity, and energy, because the sabot 'drops off' the bullet very soon after exiting the barrel. You can download my POWLEY Powder Charge Calculator : spreadsheet, format file, and text file. Loading data is also available from the folks who sell the sabots:

Your barrel should be squeaky clean when firing sabot rounds. There doesn't seem to be much friction or barrel fouling when firing the sabot rounds. Some people have reported little to no nylon fouling. I have 'moly' coated my sabots and (as one would expect) have seen no fouling. I do not know if moly coating is necessary, but I suspect that it may aid in a smooth sabot/bullet release. As you may (advanced loaders should) expect, relatively fast burning powders are called for when loading these rounds.

I see seating depth as a possible problem with sabots. Since the sabots are relatively short, you must make a trade-off regarding the amount of 'bullet' in the case neck (for proper initial bullet/bore alignment), and the size of the bullet-to-lands gap that the sabot/bullet must initially jump. I started off seating the bullets out as far as possible while still giving the case neck something to grab, and am gradually seating them deeper until I find peak accuracy. I have found that the deeper seating noticeably improves (minimizes) bullet runout, and accuracy.

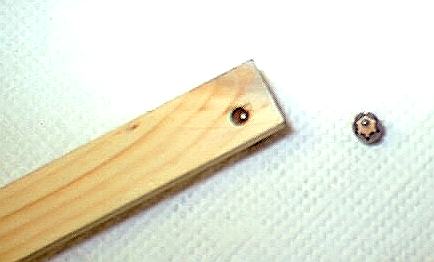

As for actually seating the sabot/bullet, I use a regular .308 Win seating die. It may be a good idea to replace the stem with one made for .224 bullets. I'm not really sure if it matters, but my seating stem is pushing on the sabot, and not the bullet. As long as the bullet is not deformed, it should not matter either way. The E. Arthur Brown Co. sells a Bullet/Sabot Seater Die for about $15. This device is for seating the bullet into the sabot, and not for seating the sabot/bullet into the case. Before I knew this tool existed, I made my own simple device. I took a thin piece of wood (pine, but any wood should work fine), and drilled a 5/32" (0.156") hole in it. I place the sabot on my bench, place the 0.224" bullet in the sabot, place the (undersized) hole over the bullet, and press. This tool is also listed on my Nifty Tools page (have a look). It works for me, and it's cheap.

When loaded, concentricity and runout is critical. Check this with a dial gauge on the bullet tip and rotate the loaded cartridge in a v-block. Runout tolerance is .000-.001". You can adjust the runout by lightly tapping the bullet and rechecking the runout until it falls within tolerance.

Last updated : 14 July 1999