Although a lathe is considered by some to be the most versatile screw machine, most modellers do not feel they can justify the cost. But since many detail parts and other applications can be turned freehand, very useful makeshift lathes can be developed from rotary tools clamped in place.

For those who require more accuracy, many model sized lathes with various features are available at a reasonable price. One step up are jewelers lathes for free hand turning. Screw machine lathes are offered by Taig, Sherline, Emco-Meir (Edelstaal-Unimat, Maximat, Compact 5) and others. These provide very accurate positioning of the cutting tool through threaded feed screws. My friend, Fritz Laufer, has done some excellent work on the relatively simple Unimat 1. Good used (not abused) units may be found. Examine the specifications and features carefully after some research. Your desires, ability and pocketbook will be the determining factors.

Caveat: All power tools should be

fed through foot speed controls or switches to provide emergency

stops, which can help avoid injury or damage. These are much faster

than fumbling for hand switches.

Caveat: All power tools should be

fed through foot speed controls or switches to provide emergency

stops, which can help avoid injury or damage. These are much faster

than fumbling for hand switches.

MAKESHIFT LATHES

Some very fine work has been accomplished with setups as these by outstanding kitchen table, loco scratch builders like Mel Thornburgh (circa 1938-1959) and Robin Love. Everything, from marker and head lights, brake cylinders, air tanks to number plates, can be turned with a little practice. The basic process is very similar to wood turning. Possibly not very efficient, almost any sharp cutting tool such as a knife tip, file or graver can be used, preferably with a rest or other place to steady it. Chamfering shaft ends can be accomplished easily with draw filing or stone grinding. Sanding cloth strips can be used to polish rough castings or turnings . One major problem is determining how to chuck the piece.

Note: Adjust brightness and contrast for optimum viewing.

FILING CHAMFER USING FOREDOM HANDPIECE CLAMPED IN HOLDER

Stone is used for hard steel axles and shafts.

The holder above clamps to bench. Lower knob clamps 12" rod permitting hight and horizontal rotation positioning. The hand piece has a Jacobs chuck ranging from 0 to just over 1/8". Visible is the shell notch which stabilizes the inserted key.

Note: Adjust brightness and contrast for optimum viewing.

DREMEL CLAMPED IN HOLDER

The Dremel holder sits on the bench and with a ball swivel permits positioning at almost any angle

Note: Adjust brightness and contrast for optimum viewing.

MAXICRAFT LATHE READY TO TRUE SCRAP PLASTIC RUNNER FOR MAST OR PIPE

Maxicraft provides this simple, but flexible, lathe accessory similar to a wood lathe with a dead center to stabilize longer pieces. The small 3 jaw (screw) chuck mounted in the tool chuck can offset for turning eccentrics. The support bar is used as a rest.

Note: Adjust brightness and contrast for optimum viewing.

MAXICRAFT LATHE IN ALTERNATE POSITION

Since the left riser plate has a hole through it, the rotor tool can be mounted with its nose through it. Another tail screw mounts a small collet chuck for drilling. A small plate with drive pin can be used between centers (upper center left). The 3 screw chuck can be mounted in the tail chuck with an offset dead center to aid long taper turning for line poles.

BACK TO ROTARY TOOLS

SCREW MACHINE LATHES

At minimum, tool holder positioning is accomplished by a longitudinal and a cross feed screw. Often a compound feed accessory is offered for taper turning. Taig offers an inexpensive unit with these and some accessories. Sherline offers a convertible unit similar to Unimat with a wide range of accessories. Many accessories can be adapted from one to the other with some ingenuity and work.

Although not as difficult to use as some would like you to believe, an amount of reading and practice is required. No attempt will be made to teach the fine art of turning. The manuals explain enough to get you started and experience is still the best teacher. Only units that I own and use will be illustrated.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT SL WITH THE JIG SAW IN LATHE SETUP

The tailstock and carriage are moved to the right for clearance. Only the power feed belt must be removed, since its pulley (on the lower left) no longer lines up with the driver spindle pulley when the housing is moved to the right to provide purchase for the saw clamp. The power feed shaft runs across the front, just below the carriage, supported by 2 pedestals . At the right is the worm driven take off shaft, whose worm drives the longitudinal feed screw. The geared feed wheel and its manual handle are obscured by the shaft housing. Just below is the round knobbed lever in the down (disengaged) position. On the carriage is the standard tool holder.

All 3, the Unimat DB, SL and 3, can be setup as a precision lathe with a runout of about .0004". The latter, more robust provides a 3" swing over the bed and with the headstock raising block about 4". All can thread with an accessory set of thread chasers. Taper turning is accomplished by rotating the headstock, allowing work to be mounted in either a 3 or 4 jaw chuck, rather than offsetting the tailstock and turning between centers. Straight 1/4" tool bits are standard. Most units are calibrated in metric. A collet set is available for more accurate chucking.

Note: Adjust brightness and contrast for optimum viewing.

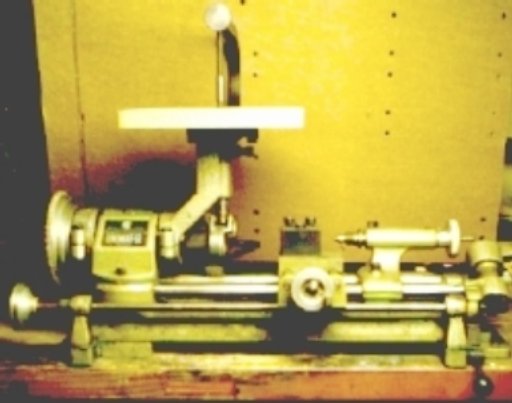

COMPACT 5 with splash guard mounted on solid old desk to provide convenient drawers for accessories.

In the notch between headstock housing and splash guard is the power switch, showing why a foot switch is safer. Belts and gears are accessible behind door on extreme left. Power feed engagement knob is on lower left. The glare from a 3-jaw chuck is just visible in front of the motor. On the carriage is a milled down riser block to accommodate the dual tool post clamp mounted on it. Between the tailstock live center and the post is the vertical column mounting clamp. Behind the tailstock handwheel is a magnetic base indicator holder.

We opted for the C-5 and companion C-5 vertical mill instead of a Unimat 3 to handle larger work and reduce machining time. These may be considered overkill except for larger scales. The trade off is a less sensitive "feel" in feeding more delicate applications. This unit is a flexible lathe with a column mount for a vertical mill or tool post grinder. Speed change is by belts and pulleys. Longitudinal power feed is by gear change permitting cutting of both ASME and metric threads plus a wide range of feeds for turning or milling. Motor is reversible permitting back turning and power rewinding of longitudinal feed. A compound feed is used for tapers. Both head an tail stocks have Morse tapers to allow use of other brand accessories. Standard straight 3/8" tool bits can be used. A collet set, up to about 3/8", is available with holders for both lathe and mill.

Note: Adjust brightness and contrast for optimum viewing.

PRE-DRILLING BARSTOCK FOR DIE HOLDER TO ALLOW BORING BAR ENTRY

Over sized 3/8" Jacob's chuck is mounted on Morse taper mandrel in tailstock.

Bar has not been cut to length nor faced. The bit size is to clear screw stock. Dark hole behind bit end, mounts vertical column.

BACK TO FILES

BACK TO METHODS

DRILLING LATHE

BACK TO ROTARY HAND TOOLS

BACK TO TOOLS INDEX