Over the years in our hobbyshop, we have tried and demonstrated practically every miniature rotary tool on the market. Some were not even acceptable and were soon returned. With the extremely extensive range of bits available these tools are very useful and efficient in time and effort requirements. There are several criteria that determine usefulness and acceptability of any rotary tool, some of which apply to others including bench types.

First is runout, wobble or how true the tip piece turns. When using small drill bits, any wobble can easily break bits or enlarge holes. Cutting edges of burs, saws, sanding drums or other circular bits may not contact surface completely during revolution, causing bouncing and uneven wear or surface finish. Both axial and radial play should be minimum for accurate work. Many sleeve bearing units have excessive play.

Grip should be comfortable and balanced, especially for delicate or long term use. This is important, not only in the common pencil grip, but also odd grips that may be required. In many cases, center of mass is a considerable distance beyond crook of hand, which tends to lift tip when cradled. Even the power cord may add to the tendency . Fingers should be as close to tip as possible without danger of injury. Some tools have snap-on extensions to permit closer grip.

Size and weight can effect usage. Larger and heavier tools may be cumbersome and decrease feel in delicate processes in any grip position. Among the better choices in their categories:

BULK COMPARISON

Smaller Maxicraft 5.5 oz.

Larger Maxicraft 11.25 oz.

Boehler Minitool 6.0 oz.

Dremel 280 ball bearing 12.25 oz.

It appears that another MBA has decided that the new trend to sell more rotary tools is to apply a pistol grip. These may be very handy on powered hand drills, but they are very clumsy when manipulating a unit in delicate work. Their major merit lies in aiming a bit, when drilling a hole. The Boehler Minitool pistol grip can chuck a 1/4" bit and has a switbable 8:1 gear reduction to increase torque and reduce speed.

Note: Adjust brightness and contrast for optimum viewing.

MINNITOOL DRILL

At the left end of housing are two dove tails for aligning and mounting on drill press

Chucks are very important for holding bits securely and truly.

Most Dremel units have been supplied with collet types chucks, which require changing, when different bit shanks are used; but may provide less runout. Unfortunately shank sizes my be inch or metric and collet ranges may not cover all, particularly with drill bits. Very few standard collets provide ranges for smaller bits.

Collets have always been a problem. Over the years we had to stock 3 different types in 4 sizes for Dremel. Each was supposed to be an improvement, but none released shanks well. Too often they had to be pried from the socket and worked free externally.

Note: Adjust brightness and contrast for optimum viewing.

COLLETS

Possibly not quite as convenient, when changing the same size shank, some adjustable chucks can handle shanks from 0.0 to over 1/8", permitting additional use with drill bits. Newer ones run as true as collets and fit most rotary tools including Dremel. They are only slightly bulkier.

Note: Adjust brightness and contrast for optimum viewing.

ADJUSTABLE CHUCKS

Adapter to enable use of small drill bits.

1/8" shank in case threads are not compatible.

Adapter for 1/4" hex screw driver.

In many cases, key or keyless three jaw chucks are available for quicker changes. Key types are more secure. However some chucks do not close down to zero or small enough to handle fine drill bits. Fine chucks are offered with shanks to fit collets or threaded to replace supplied chucks. A good source for collets and chucks is www.micromark.com.

Bearings may be critical. Well made, sleeve, friction bearings may be acceptable on smaller tools using light pressures. Careful attention should be paid to any increases in heat or noise, suggesting excessive pressure or need for lubrication. Ball, needle or roller bearings usually provide truer running, accept more pressure and require little or no lubrication.

Preferably RPM should be controllable to suit requirements. Slower speeds may take longer to complete a job, but permit finer control. Since cutting speeds are measured at perimeter of bits, as bit diameter increases, excessive speeds, of 30000 or 35000 RPM or even 12000, may melt plastics or burn work or bit. Check for heat build-up frequently. Bench, knob speed controls are fine for continuous speeds, but variable foot pedals provide readily changeable speeds during cutting, while freeing both hands. Particularly with AC units electronic triac circuits are far superior to rheostats in power consumption and low speed operation. The output pulses tend to jog armature, producing a steadier rotation. Speed controls built into tool cases are less convenient than external types for quick changes, since they require both hands. Controller must be rated high enough to handle tool during long term and continuous operation.

Tool power output should be sufficient to handle job. Smaller tools will not handle large or coarse bits with higher pressures for bulk material removal, even though they may be chucked. Excessive heat build-up may ruin motor or bearings. Most DC controllers have overload protection, but many are designed to handle larger units in the same line or series and thus do not protect smaller units. Dremel's AC controllers have much higher ratings than their rotary tools. Heat will be the first warning. Power comparison may be confusing, since most imported units are rated in watts; while domestic are rated in horsepower. 75 watts approximates 1/10 horsepower. Some units are rated in input, while others are in output power.

A final criterion might be availability of accessories. Some tool lines offer a wide selection of miniature holders and tooling to extend usage and reduce need for multiple tools. Most offer DRILL PRESSES with or without tilting ability for angle drilling. Most offer bench or vise holding clamps to position tool for two hand holding of parts. Some offer SIMPLE LATHE SET-UPS for free hand turning. Shaper tables are common. Router attachments are usually available. Sizes of these vary greatly and may be critical.

Maxicraft offers two sizes of variable DC power pack speed controlled tools with excellent runout. Both have keyless, three jaw chucks ranging from zero to about 1/8", which with care permit drilling #80 holes.

With a very comfortable grip and very light weight, the smaller rests and balances lightly in the crook of the hand, permitting a very fine "feel" for any delicate, freehand operation. With enough power to drill mounting lug holes, it is ideal for adding details to cast loco parts plastic wood, zamac or brass. Although it can be used with the accessories, this is usually relegated to the larger.

The larger is better balanced than most Dremels in that the center of mass rests almost in the crook of the hand. Except for heavier weight, the feel is nearly as good as the smaller.

The Minitool shown above performs and feels as well as the smaller Maxicraft.

For heavier work, the ballbearing Dremel 280 was chosen for durability and better runout. With a foot speed control, it was chosen over the 380 with inaccessible speed knob. Although it is too bulky for most fine work, it has filled a gap below full sized power tools. The router attachment easily grooved 1/8" slots for sliding doors when the full sized router proved unwieldy. With the wide variety of bits, burs and saws, it can perform many, otherwise difficult, jobs in tight spaces.

The center of mass is far to the right of the hand support, tending to lift the bit end, producing an insensitive feel.

There seems to be a trend toward the use of pistol handles with triggers. While these perform well and comfortably for hand drilling, they are awkward in fine model work and do not permit the sensitive maneuverability of the pencil grip.

There are several inexpensive, small battery powered erasers and sanders that can be used to remove lettering or unwanted paint.

Note: Adjust brightness and contrast for optimum viewing.

OLD ERASER W/ BRUSH TIP

Note: Adjust brightness and contrast for optimum viewing.

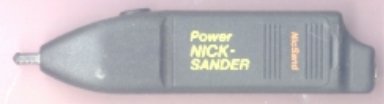

POWER NICK SANDER

Abrasive filled, rubber tip can be replaced with an eraser for lettering removal.

Often it is desirable to hold the tool stationary and feed the work into it, as in quasi lathe turning. Most lines offer bench holders, some with adapters for other sized tools.

Note: Adjust brightness and contrast for optimum viewing.

DREMEL HOLDER

Many have ACCESSORY ROUTER, SHAPER OR JIG SAW STANDS.

Some have ACCESSORY LATHE SETUPS .

Another variation is to hold tool rigidly and feed it into work as with a DRILL PRESS .

There are a myriad of BITS for cutting, carving, sawing and grinding. The only problem is: shank diameters vary and not all are compatible with all rotary tools.

BACK TO PORTABLE POWERED DRILLS

BACK TO POWER ABRASIVE SHAPERS

BACK TO TOOL INDEX