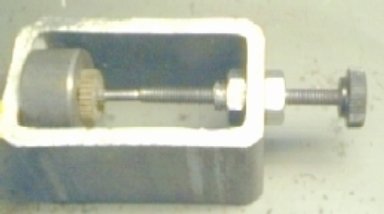

Press is made from 1.5" x 2.5" steel tubing with ideas from NWSL. A 5/16 x 1/2 screw was drilled and tapped 10-32 on an EMCO Compact 5 lathe. Screw length was determined by length of full threads on tap. This would be mounted in a hole set back to just over the nut diagonal length. The hole was drilled clear through the opposite face, on the next to last pass, with a 5/16" bit, which is the tap bit for the 3/8 x 16 backup set screw. The top hole was enlarged to 11/32" clearance for final adjustment allowance. After tapping the set screw face and cleanup, a bored set screw was mounted. A tapered end 10-32 screw was threaded through the loosely mounted hex screw and fed into the set screw bore. Then the nut was tightened. If you don't have access to a lathe, the press screw hole may be drilled and tapped, very carefully, directly in the tube face with practically no loss in accuracy.

The only secret is to use readily available screws to allow the production of various combinations of press screws and setscrew backup dies. The press screw is interchangeable with NWSL Puller.

Various length setscrews can be selected to suit needs.

If you can't find longer setscrews and you are not bothered by protruding heads, any type screw may be used.

Pressing gear with NWSL Aligner

Pressing and gauging wheel on needle point axle, using notch clearance.

BACK TO SCREW PRESSES

BACK TO METHODS

BACK TO TOOLS INDEX