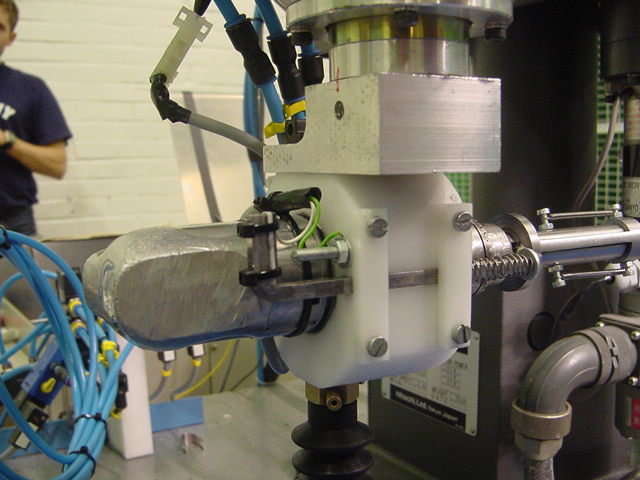

Rocco is a combined driller and tapper. It is attached to the Hitachi robot instead of a ordinary gripper. The robot is used to move it to the pump. When it has arrived in front of the cylinder, the Hitachi connects the air to the pneumatic driller and starts to feed it into the pump.

When the tapper reaches the pump, it continues to screw itself into the pump cylinder. Simutainiously, the sledge (red on the IDEAS drawings) is sliding away from the driller.

To stop the rotational motion of the driller, there is a contact that closes (pink) when the slide has reached a specific point on the drilling device. The Hitachi is containing its motion, so that it is certain that the tap is all the way through the pump cylinder and then stops.

To be able to unscrew the tapper without damaging the threads, the Hitachi moves the driller away from the piston. This stretches the spring that holds the slide back. After that, the Hitachi puts on the airflow for the reverse of the device, and the driller is unscrewed like an ordinary screw.

Schaggy

Schaggy is a vaccum device that lifts up the package plate and the repair kit. It is controlled by the hitachi with on/off signals from the PLC, that connects the air pressure to its vaccum device. The only disadvantage with this solution is that it takes a few seconds for its sucking force to release the plate and kit. The Hitachi then pauses for a few seconds in order for the sucking force to stop.