After a few days of brainstorming about how to assembly the gasket to the piston a few ideas came up, some were more realistic than others and worth to continue working with.

We understood in a early stage that the gasket could be very troublesome to handle with the robots, due to its shape and offcourse softness. The simple plan was just to have a tray magasin. To refill gaskets we just need to change tray. A disadvantage with this plan that the robot needs to move to a new point every time for picking up a gasket. A self-feeding, self-positioning fixture/magasin is to prefer.

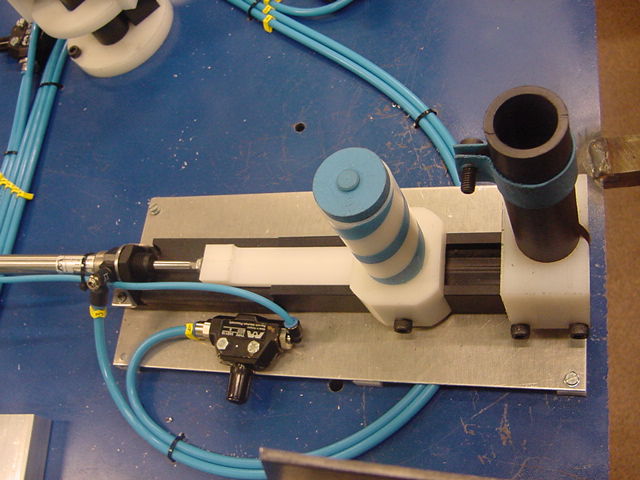

This fixture/magasin will work like this, the gaskets are piled up in a tube and a pneumatic cylinder will make a shuffle press the buttom gasket to a fixed point, where the assembly is taking place. The piston will just be pushed on the gasket directly to avoid the risks with letting the robot (Motoman) grip and move the gasket. Then assembly is done, the cylinder goes back and the next gasket falls down, gets pushed forward and mounted, this repeats over and over....

The forces on the fixture ain't so big, so plastic will be used as consruction material.

- After a few tests one problem that accured frequently was that the gaskets flipped over due to the shock from the shuffle. This problem is solved by putting a cover on the tube. The cover has a pin that goes through the gaskets wich preclude the gaskets from flipping. The pin goes to the very bottom of the tube, just so the shuffle, and gasket, easily can slide under and feed new gaskets, and on top of the gaskets ios a nut placed (used as a weight). The airflow in the cylinder is also controlled by a air pressure regulator.