I wouldn't recommend that the first time rocketeer try these advanced designs but I wouldn't want to leave them out for selfish reasons.

SCREAMIN' SLEEVE **New for 2003!!!**

Add a whistling "scream" special effect to your rocket with a few add ons.

I found a "Vortex" foam football in the toy isle of a local department store. Some of these footballs have several "Howler" buttons in them that whistle when you throw them. Simply remove the buttons from the foam ball. You may have to pull hard, because they are glued into the foam. Cut small holes into a 2 liter sleeve you made and hot glue the buttons into the openings. Finally, attach the SCREAMIN' SLEEVE to the top of your pressure chamber.

Double

Rocket/ 4-Liters of Fury

Double

Rocket/ 4-Liters of Fury

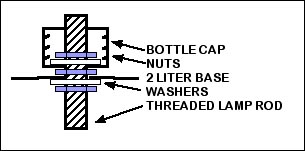

The first advanced project is a double pressure chamber. This double rocket is a 4-liter dynamo. Two 2-liter bottles are joined by a small piece of 1/8 inch threaded lamp rod. I found several versions of these plans online, but the best, and I suppose the original plans should be credited as "The Robinson Coupling". The hardest part of this project is sealing the joint where the couple is located. The air pressure inside the container needs to hold at 100 psi. I have found that PL Premium Construction adhesive is flexible and strong enough to hold the seal. Be patient, the adhesive needs at least 24 hours to cure. Don't pressure test until then.

The coupler can be made one of two ways. Either by joining bottom to bottom, or bottom to top. I will describe the second of the two.

PARTS LIST:

(1) 1/8 in X 2 inch Threaded Lamp Rod

(3) Lamp Rod Hex Nuts

(2) Nylon Washers

(1) 2 liter bottle cap

Teflon tape

Building the "Robinson Coupler"

Start

by carefully drilling a 1/8 in hole in the bottom of the 2-liter pressure

chamber and the bottle cap. The lamp rod should just barely fit into the

holes. Be careful not to remove the blue plastic gasket at the bottom of

the bottle cap. (It will help seal the joint in the end.) Dry fit all parts

to make sure it will work before you go any further.

Start

by carefully drilling a 1/8 in hole in the bottom of the 2-liter pressure

chamber and the bottle cap. The lamp rod should just barely fit into the

holes. Be careful not to remove the blue plastic gasket at the bottom of

the bottle cap. (It will help seal the joint in the end.) Dry fit all parts

to make sure it will work before you go any further.

Wrap the entire length of the lamp rod with a couple layers of Teflon tape. Thread one of the hex nuts onto the stem of the lamp rod until you get to the half way point. Set aside.

Carefully push the first nylon washer into the neck of the main pressure chamber. You will need to use a socket and wrench with one or two socket extensions to reach the bottom of the bottle. Balance a nut and the washer on the head of the socket and place the threaded lamp rod into the hole from the top down. With the skill of a surgeon, drive the nut and washer onto the rod. Tighten with a wrench on the outside surface. (At his point you could add a small dab of PL Premium Construction Adhesive to seal. PL cures with the water vapor in the air. So, if you get it on your fingers, don't try to wash it off with water. It will just set faster. You will need to use a solvent, like paint thinner.)

It will be necessary to shave down the second nylon washer to fit inside the bottle cap. The second bottle must be able to screw into the cap all the way down to the gasket. Sometimes the washer sticks out too much. Apply the washer and the nut and test fit the second bottle to make sure it seats well. If the second bottle sits crooked, then it is hitting the washer. Remove assembly and shave the washer again. Once you have the right fit, tighten the entire assembly.

Tomy

Timer

Tomy

Timer

The second advanced project is an automatic parachute

release timer. Taken again from the vast resources on the net, this project

utilizes the "guts" from a small wind up child's toy. Many of these toys

were made by the TOMY corporation, hence the name Tomy Timer. Find a wind

up toy and carefully crack it open. Remove the nickel sized timer package

from the toy case. You can remove the extra cams from the surface of the

timer, but don't cut the main winding shaft.

With

a very small drill bit, drill a hole into the plastic twist knob. Superglue

a small wire (paperclip) piece into the hole. This will serve as the loop

catch for the timer system. Next use straight pins to attach the timer

to a small section of plastic bottle scrap or cardboard. This will serve

as a platform to anchor the timer to the side of the rocket.

With

a very small drill bit, drill a hole into the plastic twist knob. Superglue

a small wire (paperclip) piece into the hole. This will serve as the loop

catch for the timer system. Next use straight pins to attach the timer

to a small section of plastic bottle scrap or cardboard. This will serve

as a platform to anchor the timer to the side of the rocket.

Next

cut a small thin wedge from a scrap piece of bottle plastic. Use this to

slip inside the gear box and jam the gears. This will allow you to wind

the timer, but not let the timer spin down. The gear slip will be tied

to the launcher and get pulled out once the rocket leaves the launch pad.

Next

cut a small thin wedge from a scrap piece of bottle plastic. Use this to

slip inside the gear box and jam the gears. This will allow you to wind

the timer, but not let the timer spin down. The gear slip will be tied

to the launcher and get pulled out once the rocket leaves the launch pad.

How to use the timer

I like using this timer in two ways. You can either build

a side mounted parachute (my personal favorite) or use the timer to physically

release the nose cone.

A side mounted parachute system uses the fins to hold

the parachute to the side of the rocket. Tape a rubber band to the bottom

of one of the fins. Stretch the rubber band diagonally upward over the

folded parachute. Then loop the rubber band over the top of the second

fin. Tie a small piece of string to the end of the rubber band and then

tie a small loop at the end of the string. Wind the timer with the gear

slip jammed in the box. Put the string loop around the timer knob and over

the loop catch. The more turns you take, the longer the timer will hold

the chute in position. After the gear slip is removed, the timer will turn

down and at some point the string loop will slip off the loop catch. The

elastic band springs away and releases the parachute.

The

nose cone release method uses a shock cord (large rubber band) to pull

the nose cone off the top of the rocket. First we need to alter the nose

cone. With a hole punch, punch two holes in the nose cone about 1 inch

from the bottom edge on opposite sides of the cone. Bend a couple of paperclips

so that you make a letter "T" from them. From the inside of the cone, push

the bent paperclip through the hole you made.

The

nose cone release method uses a shock cord (large rubber band) to pull

the nose cone off the top of the rocket. First we need to alter the nose

cone. With a hole punch, punch two holes in the nose cone about 1 inch

from the bottom edge on opposite sides of the cone. Bend a couple of paperclips

so that you make a letter "T" from them. From the inside of the cone, push

the bent paperclip through the hole you made.

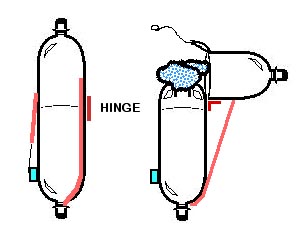

Apply

a piece of tape to the back of the clip to hold it in place. Do the same

for the other hole. Next, build a hinge for the nose cone. Take a 4 X 2

inch strip of chipboard or posterboard and fold it sharply in half. Place

the fold on the bottom edge of the cone, under one of the holes you made

earlier. You might have to trim the hinge to fit. Tape it securely to the

cone. Place the cone on the rocket body and be sure it sits lightly of

the top of the rocket. Use tape to secure the lower part of the hinge onto

the rocket body.

Apply

a piece of tape to the back of the clip to hold it in place. Do the same

for the other hole. Next, build a hinge for the nose cone. Take a 4 X 2

inch strip of chipboard or posterboard and fold it sharply in half. Place

the fold on the bottom edge of the cone, under one of the holes you made

earlier. You might have to trim the hinge to fit. Tape it securely to the

cone. Place the cone on the rocket body and be sure it sits lightly of

the top of the rocket. Use tape to secure the lower part of the hinge onto

the rocket body.

Mount the timer low on the rocket body opposite of the

hinge. Turn the rocket over and work on the side opposite of the timer.

Tape a large rubber band to the bottom of the rocket. Stretch the rubber

band up to the hole you made in the nose cone and attach the rubber band

to the hinge side paperclip. Test the hinge you made. The large rubber

band should pull the nose cone back exposing the parachute bay. If the

nose cone doesn't flip off, then adjust the stretch of the large rubber

band to loosen or tighten the system. Now create a counter resistance pull

on the timer side of the rocket. Tie a small piece of string to a medium

rubber band. Tie a loop in the string to wrap around the loop catch. Attach

the medium rubber band to the opposite side of the nose cone via the other

paperclip, then pull the rubber band down to reach the timer. Adjust the

tension of the counter resistance by shortening or lengthening the string.

Wind the timer, and wrap the string around the twist knob. Place the string

loop over the loop catch.