WATER as FUEL - WATERFUEL - WATERCAR - WATERGAS - WATERBURNER - WATER FIRE - WATERPOWER - WATERBREAKER - WATERERA - WATERMOTOR - WATERENERGY -

---------------------------------------------

Home -Introduction -Conclusion -Site Map - Links

Water Electrolysis Systems - Water Explosion Systems - Water Plasma Systems - Other Water Dissociation Systems - Other Systems - Other Fuels

---------------------------------------------

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

PLASMA SYSTEMS for FUEL TRANSMUTATION and WATER SPLITTING :

# - 1974, Jean CHAMBRIN & Jack JOJON, France, car running with 60% of WATER.

Patents : WO8203249A1: "A reactor for transforming water and carburant for use as a fuel mixture", and WO8204096A1: "A reactor to transmute the matter which using any fuel in its solid, liquid or gaseous state"

Abstracts translated from http://quanthomme.free.fr/energieencore/carnet17.htm in french :

Everybody has heard about CHAMBRIN and his 'water-engine'. As I found an original old article (from magazine 'L'automobile' n 338, jully 1974), I submit it to you, along with some commentaries. You'll see how it's rich of knowledge.

… 'An engine that runs with 60% water and 40% alcohol'…

System discovered during the 'oil crisis' of 1973, the 2 French men just saying : "You see it's not so difficult !" (means to run a car without oil ...)

… Chambrin : in 1957, you remember we were already talking about an oil crisis. But at that time I missed many things to do it. Jojon was one of my customers at the car workshop; electronic is his passion. And you know, the modern mechanic is nothing without the help of electronic, like an horse without rider. We had talks, and the result is that.

…there is 2 parts in the system; one is mechanic, the other electronic The mechanic part is a 'cracking room' like a Seguin's marmite. The electronic part is where we send a High Tension, few kilovolts, at few pico-amps, at High Frequency. the concept is that water cracking occur at 2000-2300 degree, so we need to reduce this cracking temperature, like they do in the Big Reactors at very high temperature or through 4 to 5 reaction at 730 or 1050 degrees to crack the water.

… we thought like this; we can easily obtain 700 to 800 degrees. Then we must find an easy and cheap way to sustain this reaction and then crack the water. We thought about alcohol because it's easy to mix with water (soluble in water)… So we have a mix that goes in the admission pipe at 750 degrees and meet a barrier of potentials, I mean 3 elements, first a frequency in a way created by the light (!?! The translator doesn't understand), and secondly a High Frequency at High Voltage to crack the water, and third a Low Frequency that contain the reaction in a definite area.

… we know that some metals, like Nickel, or alloy like Stainless Steel based on Nickel, are catalysts to obtain a cracking at lower temperatures … commentary from the website chronicler, Rene.

… By our experiences, we know that a car can run with 5% of oil and 95% of water.

… We reject only water and carbon dioxide, that's all, and that's not much pollution… soon we could be able to run in closed loop, by using back the water coming out from the exhaust, needing only little add to compensate the energy loses, because no system is perfect.

… we spent nights, Sundays, and full holydays on this engine. Today it turns well, we are paid already !

see also: http://quanthomme.free.fr/energielibre/systemes/PageChercheurAEC1.htm

Remarque : Plasma is the very powerful 4th state of matter, and elements going trough it can transmute …

--------------------------------------------- Return to the top

# - 1998, Paul and Molley PANTONE, Fuel Pretreater Apparatus and method, USP 5,794,601 http://www.geet.com/self.htm (this website is sometime not accessible). The GEET Fuel Processor is a self-inducing Plasma generator.

The technology used in the GEET Fuel Processor is a combination of the most basic scientific principles, most of which falls within the normal rules and of thermodynamics. But some of the 70 simultaneous phenomenon are not found in those books, since it is the combination of events, which is the body of this discovery.

Put quite simply, the exhaust heat is transferred to the incoming fuel vapor, which must be maintained in a vacuum, and the overall configuration provides a molecular breakdown within the vacuum of all of the heavier elements. Therefore, intensifying the vacuum, the speed of molecular breakdown or reaction is magnified, and less heat is required.

The GEET Plasma unit generates several "electrical" fields at the same time while operating, some of which are in opposite direction and all are affected by the direction of mass movement as well as by the gravitational field of our planet. During lectures from coast to coast Paul and Molley have explained that it is frequency and vibration that determines the amount of plasma or energy being developed.

… During tests the over-revving to engines has startled engineers and scientists from around the world, as engines are sped up to over twice the normal rpm, and slowed down to a fraction of their normal idle speed, with no noticeable vibration. Have you ever seen a 350 Chevrolet idle at 80 rpm? We have.

… supplying the fuel into the Plasma chamber in a vacuum and through a longitudinal, natural release, causes a Radial reaction which is self induced, which creates energy as electrons are pulled into the reaction of plasma, instead of consuming energy…

… An additional stabilizing feature within our system is the natural circulation of opposing masses as a vorticular motion within the Plasma Field, … The size of the Field zone must coincide with the fuel and parameters with specific limitations, dependent on the fuel demand.

Now we should also explain that a small unit, such as a 10 hp engine can be used as a "servant" to produce fuel to be used by an un-modified larger engine or furnace, by adapting pumps and only modifying the air intake only. Thus a 10 hp engine could make the fuel for a locomotive.

… The "balance " point of a perfectly adjusted GEET Plasma reaction chamber, will give the same temperature coming out of the exhaust pipe as the ambient air, as well as the air quality should be the same or a slight increase of oxygen coming out of the tailpipe. So far the inventor has accomplished a 2% increase in oxygen coming out of an internal combustion using crude oil as fuel and a 3.5% increase using Battery acid mixed with 80% saltwater.

At the higher than ambient oxygen levels you normally find ice forming on the exhaust pipes as a normal function of this phenomenon. When the Plasma field chamber is too short or too long for the density of the fuel being used, it overheats the South end and Chills the North end of the reactor, this also causes the field to consume oxygen, instead of creating it…

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

- GEET Pantone by Jean Louis NAUDIN, famous scientist experimenter of all unusual technologies: http://jlnlabs.imars.com/bingofuel/pmcjlnen.htm

The Multi-Fuels Processor of GEET is a new internationally patented technology (US005794601A1) whose inventor is Paul Pantone. This revolutionary system allows the common 4 strokes engines to run with a water/ hydrocarbon mixture. It is able to use all types of fuels (gasoline, diesel, kerosene, crude oils and others derived from hydrocarbons...) with its endothermic plasma reactor.

The Multi-Fuels Processor allows also a significant reduction of pollution generated by the gaz exhaust of almost 85% compared to a conventional engine.

Tests carried out by many industrialists and experimenters already showed that it is even possible to make function an engine equipped with this device with a mixture of hydrocarbons (20%) and water (80%)...

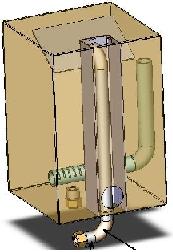

The endothermic reactor is composed of two coaxial steel cylinders:

- the interior cylinder (threaded at each end), called the pyrolytic chamber (430mm length and 15mm of inner diameter) contains a steel rod of 300mm length and 13mm of diameter (not magnetized before the burning-in). A side of this steel rod is round in order to identify its magnetic polarity after its disassembling. The rod is maintained in the center of the pyrolytic chamber with to 3 small nipples welded at each end.

- the external cylinder (threaded at each end) is a steel tube of 300mm length and 26mm of inner diameter.

--------------------------------------------- Return to the top

- Another GEET Pantone study : Final engineer studying project for ENSAIS (Ecole Nationale Supérieure des Arts et Industries de Strasbourg) Diploma by C. Martz. November 24th, 2001. http://quanthomme.free.fr/pantone/martz

"Design of a testing ground and characterization of P. Pantone's GEET process based on hydrocarbon conversion"

This testing ground has been built to characterize the GEET process by measuring definite points as, for instance, the specific consumption (i.e. output) ,different flows, temperatures, pressures, H2/O2 gas analysis...

GEET_student_test_01

… The fall of pollution on CO and HC (un-burnt) is remarkable. Furthermore on carbon gas the pollution is falling with the motor's charge (40% to 70% of diminution). Maybe the conversion reaction is more efficient when the motor is loaded (that means exhaust gas are hotter).

At this time we don't know where the rest of carbon is: a classical gas or fuel combustion give 14 to 16% carbon gas (CO+CO2), with GEET we are at 6%maximum (only CO2), which means that quantity of carbon are missing in exhaust gas...I hope that further experiences would solve this problem and say where is the carbon.

After a few hours of functioning, we have noted some interesting remarks on some rod (we got 9 rods of different dimensions):

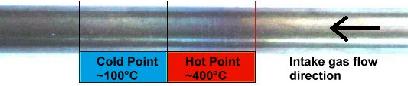

Observing a hot point on the cold side of the rod. A cold point is just after this hot point which show that the reaction has inner-reaction high temperature. I mean this hot point does NOT come from exhaust gas high temperature.

… But if really it is not hydrogen, the GEET gas is certainly a high hydrogenous gas ( smell of ether) which got the energetic advantages of hydrogen.

GEET gas coming out of reactor is more volatile and simple than the fuel and water vapors coming in. Then it is sure than there is a gas conversion in the reactor but the obtained GEET gas must be exactly definite… GEET gas is still unknown, it MUST be analysis by other ways( chemical, spectral...).

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

- SPECIAL DELIVERY from FRANCE: Le GEET c'est GENIAL ! (GEET it's GREAT !)

The French speaking people have engaged a large battle to develop the use of the GEET of the Pantones, and with the help of Mr J.L. Naudin, the website's managers of QUANTHOMME.com, Mr M. DAVID replication and tests, Mr Martz engineering study, now it's hundreds of vehicles that have been modified there, since 5 years, may be thousands …

Especially the agricultural people are adapting their tractors and machines since one of them found a simplified version of the GEET concept, that offer also enormous advantages, like reducing the fuel consumption by factor 2 to 5, and eliminating 95% of the exhaust fumes (testing with a white textile pulled on the exhaust exit, that stays white !), and without major modification on the vehicle.

They developed the SPAD, and the G-tone, that process only the water from a tank through the GEET reactor; but it seems already sufficient :

Sending some vacuum made water vapor through the GEET reactor heated by the exhaust pipe, gives EXTRA-ORDINARY RESULTS.

Modified GEET, only water is processed, fuel line not touched. (from France)

Left picture: System 'G-Tone' http://jmww.club.fr/index.html - Middle: 'SPAD' from J. P. PETIT: http://easy.spad.free.fr - Right: System 'GG' for cars

- One tractor at 1800-1900 RPM during 1h ½ of work: 7.3 l/h of diesel in place de 20-22 l/h without the G-TONE system = consumption divided per 3.

- Another tractor : 8 hours of full work, consumption in diesel was 7.5 L/Hour and 1.7L of water; before, without SPAD system, 12 to 15 L/Hour = consumption reduced per factor 2.

More links about GEET Pantone:

- a great website full of information and pictures, gathering the replications of GEET, but in French : http://quanthomme.free.fr/pantone.htm

- and THE French forum : http://fr.groups.yahoo.com/group/PMC-France/

- Mr DAVID advises and replications : http://quanthomme.free.fr/pantone/PageM_David.htm

- download of C.Martz study on GEET : http://www.econologie.com/rapport_pfe.htm

- Lorries, Boats, Big Generators can also be converted …

--------------------------------------------- Return to the top

# - BlackLight Power, Inc., From : http://www.blacklightpower.com/applications.shtml

BlackLight Power, Inc. has created a commercially competitive new source of energy. In BlackLight's patented process, energy is released as the electrons of atomic hydrogen are induced to undergo transitions to lower energy levels producing plasma, light, and novel hydrogen compounds. BlackLight uses a chemically generated plasma to form atomic hydrogen, and a catalyst to form lower-energy hydrogen atoms called hydrinos. Since hydrinos have energy levels much lower than uncatalyzed hydrogen atoms, the energy release is intermediate between conventional chemical and nuclear energies. The net energy released may be over one hundred times that of combustion with power densities like those of fossil fuel combustion and nuclear power plants.

Thus, the catalysis of atomic hydrogen, the BlackLight Process, represents a potential new source of energy. The hydrogen fuel is obtained by diverting a fraction of the output energy of the process to power the electrolysis of water into its elemental constituents. With water as the fuel, the operational cost of BlackLight Power generators will be very inexpensive. … Two of the potential applications of its technology are in the heating and electric power production.

Heat generating prototypes have indicated the BlackLight Process to be competitive with existing primary generation sources over a range of scales from micro distributed to central power generation. They have better performance characteristics than proton-exchange-membrane (PEM) fuel cells without the restrictive capital costs that arise from the requirement of hydrocarbons with the associated infrastructure and hydrocarbon-to-electricity conversion systems. The BlackLight Process thermal power source is ideal for interfacing with commercially available electric power generating equipment such as Sterling engines and turbines for microdistributed and distributed electrical applications, respectively. BlackLight has also successfully demonstrated direct plasma to electricity power conversion which is possible since the Process generates a plasma…

… As an example of the potential in the latter application, consider that the average US gas station pumps about 2000 gallons of gasoline per day corresponding to an energy equivalent of 3 MW of electricity…

Energetic Propellant:

BlackLight's experimental results provide strong support that special formulations of hydrino hydride ions may react to form the corresponding observed much more stable hydrogen molecule called the dihydrino molecule. The more stable the molecule, the more energy given off in its formation. Based on the measured energy difference between the resultant molecule and the starting reactant hydride ion, the energy release may be more than ten-times that of conventional energetic materials. A hydrino hydride-based propellant with the energy release per weight of many factors that of the hydrogen-combustion reaction currently used to propel the space shuttle may be transformational especially given the logarithmic dependence on fuel-weight to lift in the rocketry equation. …

For more details see also : http://rexresearch.com/millshyd/millshyd.htm

USP 6,024,935 (2000) Lower-Energy Hydrogen Methods and Structures by Randell Mills, et al.

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

PLASMA for COLD FUSION :

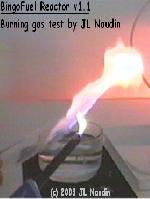

Bill Richardson, Nuclear Fusion at Low Temperature, gives a lot more energy that it uses… The gas coming out from this Underwater Plasma Electrolysis is burnable without pollution, called Bingofuel, Aquafuel, SynGas, Synthetic Gas it's COH2 (Carbon Monoxide + Hydrogen 66%, Carbon monoxide is DEADLY gas, but is eliminated when burning occur).

If the water is enriched with carbonates like sugar or sewage, the carbon electrode live longer.

# - Eco Sustainable Village Note: AQUA FUEL An Article from JL Naudin (This article is under study by our experts). http://www.ecosustainablevillage.com/eco_shop_mall.htm

Today 12-06-98, I have built and reproduced successfully a very simple AquaFuel™ generator:

"The AquaFuelTM is a non-fossil combustible gas discovered by Mr. Bill Richardson and currently developed by Technology Licensing (TTL): http://www.toupstech.com of Largo, Florida, which is produced by an electric discharge of carbon arcs within distilled, fresh, salt or other types of water, thus being essentially composed of Hydrogen, Oxygen, Carbon and their compounds". This technology has already been patented (US#5,159,900 and US#5,417,817 and US#5,435,274).

This generator produces a mixture of carbon monoxide and hydrogen (COH2) and this is a gas which burns very cleanly in oxygen or air, and it can be used as fuel for an internal combustion engine. When burned, COH2 produces carbon dioxide and water vapor, so it generates very little, if any, pollution.

Be Carefull, this device generates an explosive gas, you must conduct this test in a well ventiled room or better in open air, you must not smoke during the test.. Don't forget that the carbon monoxide (CO) is a very toxic gas, so never breath this gas before burning it.

- A 5HP Electrical Generator fully powered with the BingoFuel Reactor created on April 2, 2003 - JLN Labs. http://jlnlabs.imars.com/bingofuel/html/bfr5hpgen.htm

The fuel tank ( not used here ) has been completely removed for this test. The air filter has been removed and the synthetic gas output is directly placed at the carburetor input.

- http://jlnlabs.imars.com/bingofuel/index.htm - http://jlnlabs.imars.com/cfr/index.htm

http://jlnlabs.imars.com/cfr/ppclkrs/index.htm The experimental values recorded are the following :

The electric energy data were measured with our wattmeter UNIGOR 390 LEM. This wattmeter was tested on an ohmic heater placed in series with the CFR, so with the same perturbed current. Values obtained by boiling and by the wattmeter were in accordance within 1%.

See also http://jlnlabs.imars.com/cfr/mizuno/index.htm

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - Perreault's Cold Fusion Formula, http://www.nuenergy.org/theory/cold_fusion_formula.htm

Nu Energy Horizons, P. O. Box 22, Rumney, New Hampshire 03266-0022 USA Copyright © 2001

# -2000, ECCLES Christopher Robert ( GB ), PATENT : WO0025320 : " Energy Generation "

Abstact : Methods and apparatus are described for releasing energy from hydrogen and/or deuterium atoms. An electrolyte is provided which has a catalyst therein suitable for initiating transitions of hydrogen and/or deuterium atoms in the electrolyte to a subground energy state.

A plasma discharge is generated in the electrolyte to release energy by fusing the atoms together.

# - 2004, MIZUNO TADAHIKO (JP) :PATENTS - JP2004059977 - METHOD AND APPARATUS FOR GENERATING HYDROGEN GAS -

- WO0126117 - THERMAL ENERGY EXTRACTION APPARATUS, HOT-WATER SUPPLY, AND ELECTRIC GENERATOR - 2001

- WO9949471 - REACTOR FOR PRODUCING ENERGY AND NEUTRONS BY ELECTROLYTIC REACTION IN LIGHT- OR HEAVY-WATER SOLUTION - 1999

- JP5027062 : GENERATION OF ABNORMAL HEAT- 1993 -

--------------------------------------------- Return to the top

# - http://home.no/ufoufoufoufo/autofeed/autofeed.htm

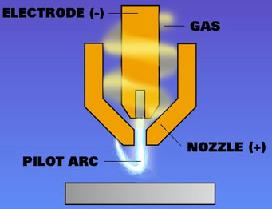

The Automatic Cathode Feed Control Circuit for Plasma Electrolysis.

A free energy friend of mine needed an automated wire feeding system. His plasma flame was so hot that the wire melted. This didn't happen at a constant rate, so he needed to automate the wire feed. My idea was using optical fibers and Light Dependent Resistor, LDRs, to detect where the plasma

flame was positioned and adjust the wire accordingly.

The actual implementation is shown next.

- More Links :

- U.S., Chilean Labs to Collaborate on Testing Scientific Feasibility of Focus Fusion : http://pesn.com/2006/03/18/9600250_LPP_Chilean_Nuclear_Commission/

- COLD FUSION BY PLASMA ELECTROLYSIS OF WATER by Ph.M. Kanarev - The Kuban State Agrarian University: http://guns.connect.fi/innoplaza/energy/story/Kanarev/coldfusion/

- The LENR-CANR home page : http://www.lenr-canr.org/index.html

- http://www.amasci.com/weird/anode.txt

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - More OVERUNITY of COLD FUSION process : http://www.mail-archive.com/interact@listserv.capital-master.com/msg00029.html

http://www.infinite-energy.com/images/pdfs/samplearticle.pdf , page 79:

"Nuclear Transmutation Reaction Caused by Light Water Electrolysis on Tungsten Cathode Under Incandescent Conditions".

Many others have repeated these experiments and gotten over 200% energy out vs in, but no one that know of has exceeded 300%.

Additional information on these experiments can be found at:

- http://blake.montclair.edu/~kowalskil/cf/74naudin.html

- http://www.lenr-canr.org/acrobat/CirilloDtransmutat.pdf

- http://lenr-canr.org/acrobat/MizunoTconfirmatia.pdf

- http://www.rexresearch.com/eccles/1eccles.htm

- http://www.infinite-energy.com/iemagazine/issue26/deviceupdate.html

- http://www.infinite-energy.com/iemagazine/issue32/iccf8.html

# - 26 other patents in COLD FUSION at one of the most large information webiste in english http://www.rexresearch.com/coldfusn/coldfusn.htm

--------------------------------------------- Return to the top

UNDERWATER PLASMA ARCING is already on the market and used to produce SYNTETHIC GASES :

# - 2005, SynGas, Canada, Discovery of Almost Unlimited Inexpensive Natural Gas Substitute, http://pesn.com/2005/05/16/6900096_Syngas/ - http://www.fairchildinternational.com/

Fairchild International Corp. acquired SynGas Energy Corp. on March 08, 2005.

No airborne emissions from inexpensive process that creates gas from biomass, waste wood, and low-grade coal, synthetic, low-cost, natural gas production technology.

The SynGas technology produces electricity and/or pipeline quality synthetic gas, … potential to replace natural gas in powering our communities, homes and industrial plants in the future. "Our technology should propel Fairchild to the forefront of the emergence of a new multi-billion dollar market for Alternative Energy…." SynGas' M-2's can scale from a small town to an entire city.

--------------------------------------------- Return to the top

# - 2001, Ruggero M. SANTILLI, MAGNEGAS, US Patent 6,183,604, 2001, "Durable and efficient equipment for the production of a combustible and non-polluant gas from underwater arcs and method therefore"

Technology called PlasmaArcFlow : http://www.magnegas.com/index.htm

Abstract from the patent :… A system for producing a clean burning combustible gas comprising an electrically conductive first electrode and an electrically conductive second electrode. A motor coupled to the first electrode is adapted to move the first electrode with respect to the second electrode to continuously move the arc away from the plasma created by the arc. A water-tight container for the electrodes is provided with a quantity of water within the tank sufficient to submerge the electrode.

… The combustible nature of the gas bubbling to the surface from an underwater welding arc between carbon electrodes was discovered and patented in the last century….

… production of a combustible gas via an underwater electric arc between carbon electrodes dates back to 1898, US pat No 603,058 by H. Eldridge… recently US 5,159,900 , in 1992, W. Dammann and D. Wallman, & US 5,435,274, in 1995, W.H. Richardson …

- from official website : Recycling Liquid Wastes and Crude Oil into MagneGas™ Fuel and MagneHydrogen™ Santilli's New Clean Fuels With Magnecular Structure

… The arc decomposes the liquid molecules into atoms and forms a plasma around the tips of the electrodes at about 10,000o F. The PlasmaArcFlow moves the plasma away from the electrodes and controls the formation of MagneGas that bubbles to the surface for collection. In this way the liquid waste is entirely eliminated from the planet …

A view of Prof. Santilli at an event organized in 2001 by the Ferrari Club of America at the Sebring International Race Track in Florida while testing a Ferrari 308 GTSi he converted to operate on MagneGas… The car runs on Magnegas at a temperature at least 25% lower than that for gasoline use… magnegas contains about 66% hydrogen that has the highest octanes among all fuel … MagneGas exhaust is generally composed of about 50% water vapor, 12%-14% breathable oxygen, 4%-6% carbon dioxide, and the rest is composed of atmospheric gases… http://www.i-b-r.org/ir00020b.htm

… In the 200 Kw version, the recycler can produce about 340 gasoline gallon equivalent (about 1,200 gasoline equivalent liters) of MagneGas per 24 hours day.

A 1 MW plant comprising four recyclers can produce up to 8,500 gasoline Gallon Equivalent (about 22,000 Gasoline Liter Equivalent) of magnegas per 5 day week.

For sales, contact : info@magnefuels.com

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - 2003, Thomas C. Kramer, Water Car-Part 7: Plasma Watercar

His concept is to put a small version of MAGNEGAS reactor in the car; he gives also other ideas…

Abstracts :… Simply, in your plasma you will get ionized and magnetized H, O and C that will reform to H2, H3, H5, H7, etc. and C=H, CO, C=O and other chemical anomalies that will occur as a direct result of the strong magnetizing forces of the plasma arc on the individual atoms allowing them to recombine using strong magnetic N-S bonding versus normal chemical (valence) bonding.

This is the result of polarizing the electron spins by the plasma arc (a high temperature N-S (+/-) magnetic reaction).

It should be noted that this 'MagneGas'™ is chemically different from the BingoGas, Aqualene, Truefuel or Carbo-Hydrogen that Richandson, JL Naudin, David Wallman, or Eldridge (1898) make from just creating an electric arc in water. Under those conditions the disassociated atoms tend to reform quickly within the plasma zone and form the normal gases that have been detected.

Buy pushing the plasma gases away from the arc zone as quickly as possible and maintaining them in an electromagnetic field, whole new species of magnetically bonded chemical formations are created!

… The consumption of the carbon rod electrodes, however, is dependant upon the amount of carbon in the fluid being subjected to the plasma arc. Plain water will eat up rods real quick. Adding sugar or even household sewage (yuk) will increase the carbon content in the water, and will work just fine in the reactor. But you can even use old cooking oil, old crankcase oil, paints and thinners, cleaning solvents and even waste garbage if it is smashed up enough to go into solution.

Comment : Plasma reactors have as much promise as resonance reactors in terms of water dissociation potentials. Both produce excessive gas over traditional electrolysis. How much depends upon system design.

--------------------------------------------- Return to the top

- MIT's Plasmatron!

In 1999 MIT researchers headed by Leslie Bromberg invented and patented a device that is supposed to attach to a carburetor that dissociates fuel via a plasma arc into a hydrogen rich fuel mix. Basically they ran gasoline through a plasma arc, causing it to dissociate some of the hydrogen before being sucked into the engine. In their experimental system they used metal electrodes that did require occassional replacement.

To get better engine performance they needed to blast about 25% of the fuel, but this did have very positive results on emissions and fuel consumption.

They also experimented with different fuels being zapped through the plasma arc but they haven't pubically divulged these results yet.

Now comes the BIG question. Did they ever use water?

I don't know. But here is an idea that you might want to try.

Kramer's WaterPlasmatron:

It seems to me that one of the simplest ways of getting a water plasma into an engine is to make it at the carburetor, like in the plasmatron example. But this requires the production of significant amounts of gas from a plasma arc as quickly as possible and on demand. Can this be done using water?

I believe so, but it requires gaseous water (steam or very fine mist) at pressure and a permanent arc zone using metal electrodes.

Steam is a bit difficult to make on engine start-up but can be easily made from recycled exhaust heat for continuous running engines. An electric heater can be used for start-up generation. But this is not too practical for a car, as you want to hop in and go.

There are a number of different types of solenoid actuated fuel injectors that create micron sized water molecules in very fine mists that are ejected at pressure and can be easily focused on a plasma reaction zone.

The neat thing about this design is that it can be small enough that multiple injectors can be bundled together to produce enough dissociated gas to run an engine.

The firing of the injectors and plasma electrodes is also easily timed to an engine rpm's. And I can wrap an electromagnet around the reactor tube right after the electrode. And any extra water vapor in the cylinders just adds to steam expansion, so that is a good thing too.

PS: Please visit Prof. Santilli's websites listed below to learn more about "PlasmaArcFlow Reactors" and his hadronic approach to nuclear, chemical and biological systems. Really amazing stuff if you are into basic math and science.

- http://www.i-b-r.org - http://www.magnegas.com

- http://www.santillimagnegas.com/ - http://home1.gte.net/science2

Prof. Ruggero Santilli has been nominated for a Nobel Prize for his contributions to mathematics, physics, nuclear physics, chemistry and astro-physics/cosmology. He has one of the most brilliant minds of our time and is well worth investigating as he has shaken the very foundations of quantum mechanics and other commonly held beliefs.

--------------------------------------------- Return to the top

# - 1995, PLASMATRON MIT (Massachusetts Institute of Technology), US5425332, "Plasmatron-Internal combustion engine system" http://www.psfc.mit.edu/plasmatech/plasmatron1.html and http://engine.mit.edu/obrien/plasmaref.html

Hydrogen via Plasma Reformers … Hydrogen is considered by many to be a nearly ideal fuel for sustainable and environmentally benign development…. has a high mass energy density, and produces no greenhouse gas emissions when combusted…. also required as a fuel for most proton-exchange membrane (PEM) fuel cells…. possible solution to the problems of hydrogen storage and transport is to produce the required hydrogen fuel on board … it must be compact and lightweight, be easily controllable, and be able to respond rapidly to changes in fuel demand.

… The reactor uses a rotated electrical arc to heat the process gases to extremely high temperatures (peak temperatures of up to 10,000 K, and mean temperatures as high as 4,000 K)…. nearly instantaneous response to changes in electrical power … The arc operates at powers ranging from 500 to 2100 watts.

An air flow is introduced from behind the cathode, and is heated as it passes through the arc. The fuel is then injected into the heated air stream, and the reforming reactions occur as the gases flow through a cylindrical reactor (30 cm in length) placed downstream of the plasma, producing hydrogen and other products from the input fuel and air … The residence times in the reactor were very short (around 200 milliseconds in most cases), and yet significant amounts of hydrogen were produced.

Get it in PDF http://engine.mit.edu/obrien/obr_hoch.pdf

- Some more links:

- MIT's plasmatron cuts diesel bus emissions, promises better gas engine efficiency, October 16, 2003. http://web.mit.edu/newsoffice/2003/plasmatron.html

- The Group of scientists http://psfcwww2.psfc.mit.edu/plasmatech/people.html

- http://www.technologyreview.com/articles/wo_savage071803.asp

- PDF about pollution reduction with the Plasmatron : http://www.osti.gov/fcvt/deer2000/brombpap.pdf

- And, Plasmatron_NOx Trap System http://www.psfc.mit.edu/plasmatech/Plasmatron.pdf

- 1999, Device could help cars' gas-burning efficiency, http://seattlepi.nwsource.com/local/plas15.shtml

… The sun and the stars are high-temperature plasmas. The light in fluorescent bulbs is a low-temperature plasma… Cohn first got the idea for using plasma technology from a former Soviet scientist he met in the early 1990s… "Skeptics said it wouldn't work because it would take too much energy to run,"… Rabinovich mentioned to Cohn how he had set up a low-temperature plasma reactor using common fuels to give his lab more than the government-allotted power supply…. In 1995, Cohn, Virden and Rabinovich joined with Leslie Bromberg of MIT and Jeff Surma at PNNL to make the plasmatron idea for cars into a practical reality. The name for the device was likely Cohn's idea … when mass-produced, should cost only a few hundred dollars…. plasmatrons might reduce the need for oil refineries by essentially making the car a "mini-refinery."

- MIT is studying use of the plasma reformer in the pyrolytic, partial oxidation and steam reforming methods mode. http://www.bellona.no/en/energy/report_3-1999/11197.html

MIT's "Plasmatron" operates at temperatures of over 2,000 oC, and the amount of hydrogen produced is around 80-90%. The main disadvantage with plasma reforming is its dependency on electrical power. MIT hopes to lower the need for electricity to 5% of the fuel's combustibility caloric value through heat recycling and a better reactor design; today it is 20%.

DOE FreedomCAR & Vehicle Technologies Program : Plasmatron Reformer Cuts Diesel Emissions http://www.eere.energy.gov/vehiclesandfuels/news/fcvt_news_110503.shtml

- http://freeenergynews.com/Directory/FuelEfficiency/Plasmatron/

Creates hydrogen on the go from fuel, using plasma technology. Three MIT professors, with DOT funding, have come up with a device that resembles Paul Pantone's Geet. Patents predate Pantone's work. Have licensed to automobile supplier, Arvin-Meritor.

The Plasmatron joined with a carburetor

# # # BUT ! WHAT THEY DIDN'T TELL YOU IN PUBLIC: but it's in the MIT patent :

abstracts : "In a Water Plasmatron, the proportion of hydrogen is increased, water vapor being the gas processed…

In the case where the highly hydrogenated gas is THE ONLY FUEL GOING TO THE ENGINE, it must be noted that the product of the combustion, WATER, feed back the Plasmatron."

It means that we can run an engine with just water as fuel, cracked / processed in the Plasmatron !!!

That's another WATERCAR recipe, and coming from the world most famous institute of technology …what do you need more to be convinced?!?

is it a provocation, or just the expression of a good sentiment that send us a signal for us to take action …

### So please, you who have enough knowledge to design a water plasmatron, like the MIT one, DO IT and GIVE IT TO THE WORLD on INTERNET, anonymously ; you won't become rich, but they won't catch you, but we will relay the information to people that will produce it and sell it to the needy; off course it won't be in America or Europe, where the bad guys have to much power, but after it been largely used in third world countries, it will be more easy to make it accepted in modern countries ; and there it will really help the needys, those that have no petrol to cook their meals, to run small factories or transportation... it will give them the ENERGY THEY NEED TO DEVELOP ! ###

Remembering that this project was financed by the US Department Of Energy, that doesn't have the reputation of a gentile one to accept the free energy systems…

See in French http://perso.wanadoo.fr/quanthommesuite/plasmatronMIT.htm

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# Also about PLASMA to split WATER :

--------------------------------------------- Return to the top

--------------------------------------------- Return to the top

PLASMA is also a very good solution to reduce wastes, plants are already running in Japan, Hawai, ... :

---------------------------------------------

Home -Introduction -Conclusion -Site Map - Links

Water Electrolysis Systems - Water Explosion Systems - Water Plasma Systems - Other Water Dissociation Systems - Other Systems - Other Fuels