Removing a large mass of material from a large surface by hand can get tiresome very quickly. For faster and lazier work, various power tools are available in reciprocating, orbital, spinning or belt types. In general orbital produces the smoothest finish. Although the prime reason for using power is faster removal, heat from excessive speed can melt plastic, burn wood and destroy temper in metal. A speed control is an absolute necessity . Very careful attention must be exercised in control to prevent damage outside working area and frequent checks should be made to avoid over cutting. Although many metal cutting bits and blades can be used for faster, rough removal, abrasives produce smoother final finishes.

Basically sanding, grinding, wire brushing and buffing are the same process; in that they all use small abrasive edges to chisel away material. Often the dividing lines between their uses are nebulous and overlapping, yielding a choice among them.

Sanding usually involves abrasives bonded to more flexible backing sheets of paper, plastic or cloth; which are frequently mounted on stiffer back-up forms, often padded. It is usually applied to larger, more level surfaces.

Grinding usually refers to the use of preshaped porous solid or embedded abrasives, more often circular and used on harder material. Grinders may be tiny shapes used on rotary tools or large disks and wheels used on specially designed machines.

In brushing the bristle ends act as fine chisels. Bristles may be steel, brass or fiberglass; often used to remove oxides and blemishes. Softer plastic or animal hair bristles are used for polishing. Sizes are similar to grinders.

Although abrasive rouges are often added, even the fibers of the buffing cloth act as fine chisels. These are normally used to produce lustrous, shiny finishes. Again buffer sizes are similar to grinders.

In all cases the abrasive edges act as tiny chisels which gouge and dig away small pieces from the work surface. Greater pressure and coarser grits dig deeper.

Probably most common in the hobby field is the use of the many ROTARY HANDTOOL (often called hand grinders) and flexible shaft tool, cutting and abrasive accessories. Mandrel mounted, these range from sanding disks and drums though a wide variety of shaped abrasive grinding wheels, wire brushes and buffers. Grits vary from coarse to very fine. Larger sizes are made to fit hand drills.

Some tools are designed specifically for sanding type jobs. Available in 110V Ac or 12V DC, for tighter spaces a changeable, snap-in tip, Proxxon Micro-sander has variously shaped pads to which precut, pressure sensitive, sand paper forms are affixed. The tip reciprocates about 3/32" perpendicular to the long axis of the tool for tight use. To permit quick swaps, additional round, square, barrel and triangular, 1/2" pads, on bent or straight tips are available. Grits are 180, 220 and 400. The 110v AC speed is adequate for normal sanding. By cutting pads from tips, felt buffing shapes may be forced on or they may be glued to pads.

Note: adjust brightness and contrast for optimum viewing.

PROXXON MICRO-SANDER

Very similar, but with reciprocating movement parallel to long axis and ball joint mounted pads on a curved rod, the Boehler Minitool (Craftsman) Detail sander operates from a variable DC pack. Ball joint maintains pad to surface contact. Set screw collet accepts up to 1/8", file or chisel tip, shanks to extend use. Saber saw blades may be chucked for pseudo sword saw use.

Note: adjust brightness and contrast for optimum viewing.

BOEHLER MINITOOL DETAIL-SANDER

Screwdriver chisel + Pads.

Diamond file.

For larger jobs, Wahl offers an AC or cordless, combination Filer/Sander tool which reciprocates along the axis and accepts mounted snap-on files or sanding wands. Files are 1 3/4", medium cut flat, triangular, round and half-round. Pressure sensitive, 5/8" x 2", precut sander sheets come in 100, 220 and 400 grit. Unfortunately no general purpose adapter is available to permit use of other tool tips. File snap-ons could be modified. Worn-out files can be ground for chisels. Sheet felt may be glued to spare wands for buffing.

Note: adjust brightness and contrast for optimum viewing.

WAHL FILER/SANDER

Small "S" hook added to cord for hanging.

Some other RECIPROCATING TOOLS can be converted to hold abrasive bits and files.

For broader coverage, the Maxicraft 2" x 2 3/4", orbital sander accessory replaces standard chuck on rotary tool. It accepts any cut sanding sheets. DC power pack adjusts speed to suit. Four rubber snubbers absorb shock and permit slight angular positioning. Mounting unit in accessory holders, it can be used as a bench sander.

Note: adjust brightness and contrast for optimum viewing.

MAXICRAFT PAD SANDER ACCESSORY

Heavier duty is the Black & Decker dedicated motor, 2" x 2 3/4" orbital sander which also accepts any cut sanding sheets and DC power pack adjusts speed to suit. Four snubbers are also present. Unfortunately plugs and powerpack jacks are not compatible with Maxicraft.

Note: adjust brightness and contrast for optimum viewing.

BLACK & DECKER PAD SANDER.

Minitool has a right-angle handle version with 2 1/2" x 3 1/2" snap-on pads and 3 snubbers for quick grit change. Sheets are precut pressure sensitive.

Note: adjust brightness and contrast for optimum viewing.

MINITOOL PAD SANDER.

For faster sanding on larger areas, a Minitool (Micro-Mark, Sears) belt sander cuts faster with grits of 80 and 120 and 1" x 2 1/4" flat surface. Rollers are about 7/16" R and overall length is about 4 1/2". Convex curves can be made by rocking, while concave could use roller surfaces .

Note: adjust brightness and contrast for optimum viewing.

MINITOOL BELTSANDER.

Sort of a catch all machine, this tool can be used as a 2" disk sander or buffer with rigid or flexible pads. Using chucks any rotary tool accessory may be used. Only available from Boehler in Germany, an adapter permits use of about 2 3/8" circular saw blades, which will fit in guard with cutting edge exposed at end. With a sleeve, 2" Ryobi grinding wheels will fit.

Note: adjust brightness and contrast for optimum viewing.

MINITOOL RIGHT-ANGLE GRINDER.

Often a larger stationary disk or belt bench sander is the right choice. With guides very accurate sanding can be accomplished, sometimes too quickly. Speed control is very important. With finer grits these can be used very effectively with metals to remove sawing burrs and scars, chamfer, true cuts and sharpen tools..

Disks are normally used for finer, straighter edges and surfaces. Convex curves can be made by pivoting work. Compound angles can be made by tilting table using miter guide on table. With the normal counterclockwise movement, sanding should be done to the left of center. Upward movement, to the right, tends to lift work piece. Do not force work. For better results let the speed of the machine do the work. Disks are usually pressure sensitive, but newer types have a velcro type backing for quicker changes. One inconvenience with most disk sanders is that the table must be removed to change sanding disks.

Belts are used for faster cutting, rough work. The top pulley area can be used for concave curves. To assure straight vertical faces, the backup platen should be adjusted to just clear the back of the belt. For strapping, polishing and convex curves the platen may be moved back or removed. Normally belts can be changed easily through a side door.

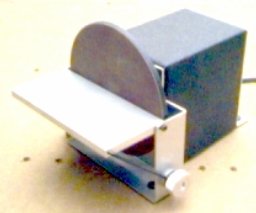

Power-mite offers an inexpensive 4" disk sander with a simple AC motor mounted in a sheet aluminum box. The tiltable table is mounted on another affixed, bent sheet with pivots and adjustable braces. No guides are provided. One can be made easily from a short, flat bar screwed to the table. It handles most model sanding well. A similar machine could be made with a DC motor for better speed control. Minicraft offers a similar DC model. Larger, much more expensive disk sanders can not really be justified for typical projects.

Note: adjust brightness and contrast for optimum viewing.

POWER-MITE 4" DISK SANDER.

Dremel offered a reasonably priced, compact combination 1" wide x 30" belt and 5" disk sander, 11 1/2" deep x 10" wide, which can handle most hobby jobs. Both tables are tiltable and the disk table accepts a miter.

Note: adjust brightness and contrast for optimum viewing.

DREMEL 1" BELT / 5" DISK SANDER.

Delta offers a more expensive and rugged combination 1" wide x 30" belt and 5" disk sander, 11 1/2" deep and 14 1/2" wide, which can handle almost any job. Both tables are tiltable and the disk table accepts a miter. Vacuum cleaner ducts remove dust on both belt and disk.

Note: adjust brightness and contrast for optimum viewing.

DELTA 1" BELT / 5" DISK SANDER.

On the layout larger sanders are helpful to make things fit. Most of the types in the model field are available in larger sizes. As drill accessories disks and drums of many sizes are offered. Back-up plates for disks may be metal or flexible hard rubber. Drums frequently have hard rubber cores. In general achieving even level surface is difficult, but they do work well on convex surfaces.

Most others are pad or belt sanders, used primarily for leveling or smoothing larger surfaces. Most are switchable from reciprocating to orbiting. For tighter places the jitterbug, palm or finishing sander is handy. Often with a triangular pad, it can access corners.

Note: adjust brightness and contrast for optimum viewing.

PALM SANDER, 4" x 4 1/2" PAD.

Often it is necessary to sand convex or concave surfaces, but flat sanders are difficult on the former and almost impossible to use on the latter. A pendulum or 3-D has 3 pivoting pads that conform to curved surfaces. Recently Craftsman released an inexpensive, AC, variable speed, model; capable of managing 4" radius curves. Several grits and buffer, Velcro mounted, pads are available. A smaller, expensive DC machine is offered by Boehler Minitool ; however, at present, it is not imported into the USA.

Note: Adjust brightness and contrast for optimum viewing.

PENDULUM/3-D SANDER

For larger leveling and finishing this 4" x 8" pad sander reciprocates or orbits. Standard cut sheets range from 60 to 400 grit. Some have built-in vacuums with bags to collect most dust.

Note: adjust brightness and contrast for optimum viewing.

PAD SANDER.

For very fast, rough work, 3" belt sanders are handy, but more difficult to control. With accessory stands, they can be converted to heavy duty bench sanders. Some also include vacuums.

Note: adjust brightness and contrast for optimum viewing.

BELT SANDER.

Grinders perform the same functions as sanders, but on harder materials and metals. Due to their porous nature, they tend to fill and clog with softer materials. Most common cutters are shaped wheels including disks, cylinders, cones, spheres and cups. Some are comprised of tiny grains bonded together to resemble solids. Others have grains impregnated in rubber. Newer types have grains bonded to metal surfaces as with diamond tools. Many, as accessories for rotary tools and drills, use fixed or screw-on mandrels. Once considered a rough process, today grinding can produce very accurate dimensions in the micron region.

Caution: As with all powered

cutting tools, suitable protection must be worn. Grinding is worse, since in

addition to flying work material chips, grains of abrasive are included.

Often very hot sparks are added to the mixture. Quasi-solid wheels demand

special care to guard then from shock. Hidden cracks may weaken them;

causing them to fly apart on spin-up. Never stand in the line of fire when

starting a grinder or you may regret it. Although abrasive accessories are

often offered for screw machines, their use is not recommended; since

ejected abrasives tend to collect on oiled ways and erode their

accuracy. Often misused with excessive pressure which over bends and

weakens bristles, wire wheels should be run a lower speeds. High speeds

will emit bristles radially like tiny spears, which pierce the skin easily.

Caution: As with all powered

cutting tools, suitable protection must be worn. Grinding is worse, since in

addition to flying work material chips, grains of abrasive are included.

Often very hot sparks are added to the mixture. Quasi-solid wheels demand

special care to guard then from shock. Hidden cracks may weaken them;

causing them to fly apart on spin-up. Never stand in the line of fire when

starting a grinder or you may regret it. Although abrasive accessories are

often offered for screw machines, their use is not recommended; since

ejected abrasives tend to collect on oiled ways and erode their

accuracy. Often misused with excessive pressure which over bends and

weakens bristles, wire wheels should be run a lower speeds. High speeds

will emit bristles radially like tiny spears, which pierce the skin easily.

Bench grinders usually have extended, threaded motor shafts used as mandrels on which shaped abrasive, wire or buffer wheels are mounted. These may be quasi-solid grinding wheels, brass, steel or soft bristle brushes, or various felt or laminated cloth buffers. Grinding wheels are frequently used to shape and sharpen lathe, drill and other bits plus many hand tools. Sides of wheels are used to form straight shapes, while edges are used for hollow ground tools. In modeling, they can be used to trim or shape parts, remove metal casting gates and perform many sanding and filing type functions on metals. Most have water containers for dip cooling to control heat. In front of the wheels are small adjustable rests to steady work pieces. Most have transparent plastic or glass shields. Several clamp-on guides are available to set angles for sharpening bits. A trip to a shoemaker's shop will reveal some excellent techniques for shaping, brushing and buffing.

Note: adjust brightness and contrast for optimum viewing.

SMALL 4" BENCH GRINDER.

Fancier models have special wheels and alignment clamps for sharpening drill bits. Other types are often found in kitchens, with specially shaped wheels for sharpening cutlery and scissors. In shops larger grinders are usually mounted on pedestals.

Thin disks are often used for cutting bar stock, tubing, cable and other extrusions. Often called cut-off wheels or choppers, sizes range from about 1" diameter on rotary tool mandrels to giant sizes in special machines. Some disks are quasi-solid abrasive, which breaks very easily under side pressure; while others are more resilient, abrasive impregnated fiberglass. They can be used on radial saws for larger work.

Very useful in hobby work is a small version which uses 2" disks for metal or saw blades for wood and plastic up to 3/8" x 3/4". A miter mounted vise varies from 45 ° to 90 °. Pressure should be light to prevent slowing motor and let the speed do the work. This produces better cuts with very little clean-up. The side of disk can be used for chamfering.

Note: adjust brightness and contrast for optimum viewing.

MITER CUTOFF MACHINE.

Since freehand carving and shaping requires an artist's touch, shaper tables can ease the process, especially with thin sheets. Industrially special machines are used. Often routers and radial saws have accessories for these. Several miniature variations of accessories are available for modellers. Any of the rotary tool burrs, sanders or abrasive shapes may be used. Some have guide fences and guards. Often drill presses con be used, but top view may be obscured. Grooves and molding type edges can be applied to metal sheets with shaped bits.

Dremel's older router attachment included instructions for constructing a small wooden shaper table. With both depth and guide adjustments it can be used freehand for edging, slotting and recessing; as well as table functions.

Note: adjust brightness and contrast for optimum viewing.

OLDER DREMEL ROUTER ATTACHMENT.

They also offer a larger, bench edge mountable, 6" x 8", table with an angle set-able fence with a calibrated, adjustable guide. An adjustable guard is mounted on rear arm.

Note: adjust brightness and contrast for optimum viewing.

DREMEL SHAPER TABLE.

The versatile Maxicraft offers a router guide attachment, with simple guide, that can be converted to a shaper table. Minicraft offers a similar setup.

Note: adjust brightness and contrast for optimum viewing.

MAXICRAFT SHAPER TABLE.

The Minitool (Sears) dedicated, plunge router can be used as a shaper by mounting unit to a table with legs or clamped to bench edge. Cutter can be set by tightening two handles.

Note: adjust brightness and contrast for optimum viewing.

MINITOOL PLUNGE ROUTER.

To avoid side thrust of rotary tool bits, pattern makers use a table with special, vertically reciprocating files, which cut on the downward stroke. But the upward stroke tends to dull teeth. An inverted saber saw, with table added, does the job well. With the newer diamond coated files, this is eliminated. File handles must be shortened to lower cutting area. Small abrasive saber saw blades can be used.

Note: adjust brightness and contrast for optimum viewing.

MAXICRAFT SABERSAW PATTERNMAKER'S SHAPER TABLE.

Three tapped holes permit mounting table made to suit.

Minitool offers a 3 1/2" x 4 1/4" shaper table attachment for their jigsaw which can accommodate a suitable diamond blade for pattern filing. The vertical piece at the right depresses switch, when rear of table is pressed down. Using a hole in the motor housing, a wire clamp holds unit on bench.

Note: adjust brightness and contrast for optimum viewing.

MINITOOL SHAPER TABLE.

BACK TO ROTARY TOOLS

Dremel once offered a vibrator powered freehand saw with 4" pin blades. It can be used in spaces where there is not enough room to use a hand saw. ABRASIVE CORD _can be used by tying knots or clamping ends with model airplane wheel collars. Very tight sanding can be done in slots, grooves and holes.

Note: adjust brightness and contrast for optimum viewing.

DREMEL VIBRATOR SAW.

BACK TO HAND ABRASIVE SHAPING

BACK TO METHODS INDEX

BACK TO TOOLS INDEX