A practical Approach

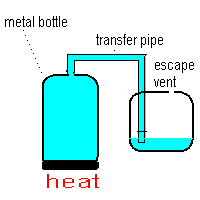

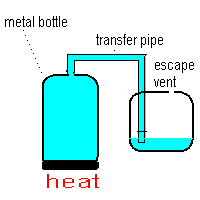

Practically this system is a pressure cooker with some additional

things.When you supply heat at the base ,the water inside will expand

HOME

resulting into flow of water through the pipe into the

THEORY

half filled container . After some time the water will start

DRAWINGS

boiling. The steam will be coming through the pipe into the cold

Phase I

water . Now some of it will be cooled and the other will escape

Phase II

through the escape vent and eventually the level of water will

PHASE III

rise . This process will continue till the water inside is

CONCLUSION

completely converted into steam . After the end of this process

FEEDBACK the supply of heat should be stopped and instantly cold water

should be poured. Within no time you will see all the water in

the container will be absorbed into the primary container due

to very low pressure developed inside ! And you will see that

whole of the container is completely filled with water.

The above thing is the only thing I did to verify my Ideas .

I tested the concept for two years with no success with

different made-in-house models using plaster of Paris,mseal for

sealing purposes . But success came after the above model was

used . I made it with welding thick support pipes used for sheds

and the normal half-inch plumbing pipes . Then I tested it on

the stove .

I observed the following working conditions :

1)There should be no air space inside the whole system i.e. the complete

system should be filled with water

2)Heat supply should be stopped when you see no bubbles(steam

bubbles) coming out at the end of the pipe after you have seen

them for a long time.

3)For quick results the level of water in the secondary container

should be just a little above the end of the pipe and the

diameter of the pipe should be very thin .

4)For more effective results you could apply the valves and get hot

steam to flow out in a container through valve 1 and cold

water to flow in through valve 2 through another container .

I did use this model but as the valves were water valves ,I

didn't get the expected result for which I had modified the

design .

In case of the temperatures required I'll say that the temperature

require for the working of a pressure cooker . In France people were

able to melt iron with the help of this energy .And also there

are companies in Australia that are using the sun's heat to

convert water into steam and using this steam to run turbines .

In my design just some modifications have been made which require

no additional heat . And about the pressures it

will simply depend upon the pressure valve used and accordingly

the generator has to be used . The Phase III has to be tested to get

further specifications .But I say that It will surely work as the

principle has been proved and theoritically it will give almost 100% more

BR>

output!