| |

|

|

|

Home

Home  Track

Building

Track

Building  Routing

1

Routing

1 |

| |

| Constructing the Track

- Routing, part 1 |

With the plan and the jigs completed,

it was time to get started.

The track surface was 1/2" MDF,

available from the local lumber yard

for about $20 a sheet.The triangular

legs and the cross members were made

from 3/4" A/B plywood.

The MDF was soft; therefore cut easily.

When routing the MDF, a lot of dust

is generated - I ended up buying a shop-vac

and a dust mask.

|

| Routing the curves |

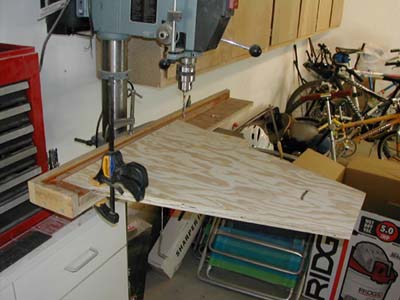

All the curves were routed using

the two "curve jigs"

described earlier.

|

Cutting the inside of a curve

blank.

|

- Mark the center of the curve.

- Using a protractor, draw

lines extending from the center

of the curve to the edges

of the curve.

- Drill a pivot hole in the

MDF at the center of the curve.

- The jig is placed in a pivot

hole in the MDF.

- Route the outer edge first,

then the inner edge.

- A clamp holds the pieces

together to make cutting the

last few inches easier.

|

|

| Routing the edges |

Without a circular saw, a straight

edge and router may be used to

cut the edges.

|

With the straight edge still in

place, the completed curve blank.

|

- The straight edge is clamped

to the curve, parallel to

the line previously drawn

for the edge, allowing for

the offset required by the

router base.

- The straight edge was always

placed on the "track

surface" side of the

edge line.

- The router was run along

the straight edge (already

complete in the photo)..

|

|

| Straights |

All the straights were cut on a table

saw. The MDF sheets were 49" wide,

since the track sections were 23 1/2"

wide, the panel was first ripped at

24 1/2". With a more managable

piece, a second pass was made on the

table saw, trimming the straights to

the exact width..

The edges of the straights were cut

with a straight edge and router, using

the same principles as cutting the edges

of the curves. |

| |

| Cross members

|

The cross members were cut from

3/4 plywood. They were 3 1/2"

tall and the same width as the

track surface.

|

Drilling the first hole.

Drilling the second hole.

|

- The cross member is placed

against the left edge of the

jig, the first hole is drilled.

- The cross member is moved

to the right in the jig, placing

the first hole on the dowel.

The second hole (middle of

cross member) is drilled.

- The cross member is moved

to the right in the jig, placing

the second hole on the dowel.

The third hole is drilled.

- Before removing from the

jig, draw an "X"

in the upper right corner

of the cross members. When

the cross members were attached

to the MDF sections, the cross

members were oriented so all

the Xs were on the same side,

providing for accurate alignment.

- The holes were 1/32"

larger than the bolts used.

This allowed the adjacent

sections to be adjusted so

the surfaces were even.

|

|

| Attaching the

cross members |

The sections are joined by bolting

the cross-members from the adjacent

sections together with 3 bolts.

The cross members also anchor

the side boards.

|

The "lead on" with the

third cross member clamped and

glued prior to drilling the pilot

holes.

|

- Place wood glue on the edge

of the cross member and the

bottom of the track surface.

- The face of the cross member

must be flush with the edge

of the track surface.

- Clamp the cross member in

place.

- Drill the the pilot holes.

- Secure the cross member

with drywall screws.

- Be sure the spacing for

the screws will not interfere

with the slots or braid..

|

|

| Legs |

The legs were made of 2 triangular

pieces, joined by 2 bolts. One

triangle had a long, vertical

slot; the other had a pivot hole

and a curved slot. When joined,

the leg was adjustable both vertically

and angled. With so many pieces,

this was a time consuming step.

Since the track had elevation

changes, the legs were divided

in to 3 categories - low, medium,

and high. The same principles

were used on all the legs, the

length of the pieces varied among

the 3 types - all the legs had

about 6" of vertical adjustment

and 15 degrees of tilting adjustment.

|

Routing the curved slot in the

leg which controls the tilting.

For the upper triangle, holes

were drilled for attaching to

the cross member using the same

jig. Since the legs were 3"

narrower than the cross members,

a 1 1/2" block was placed

in the left corner of the jig.

A completed leg attached to the

cross members. The curved slot

in the upper triangle controls

the tilting, the vertical slot

in the lower triangle controls

the height adjustment.

|

- A grid of the trianglular

pieces was drawn on a 4 x

8 sheet of plywood, alternating

the orientation to minimize

waste.

- For the upper triangle,

the piviot hole was drilled

first, the tilting hole was

drilled second, the small

curve routing jig was used

to cut the tilting slot. The

3 holes for attaching to the

cross member were then drilled.

- For the lower triangle,

one hole was drilled, a straight

edge and router were used

to cut the vertical slot

- The edges of the legs were

smoothed using a 1/4"

round-over router bit..

- For more support, "fender

washers" were used for

the 2 bolts holding the triangles

together.

|

|

|

| |

| |

|

|