|

|

Translation of 'Approval Guidelines for Intumescent Building Materials' dated November 1996 published by Deutsches Institut für Bautechnik (DIBt), Berlin, Federal Republic of Germany.

(original Title: Zulassungsgrundsätze für dämmschichtbildende Baustoffe, Fassung November 1996)

|

|

|

|

|

Please scroll down.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This preamble is lengthy, but the rest of the document may be confusing or misleading without understanding the contents of the preamble.

Note: Technical translations must strike a balance between accuracy of the reflection of the original document as well targeting the resulting document to a readership in the most comprehensible manner. In this endeavour, the translator has at times inserted explanatory text in parentheses as well as changed sentence structure. German technical documents tend to contain sentences as long as your arm. Some of these have been cut down to bite-sized chunks. Also, the reader must bear in mind that terms deemed as correct translations in any number of dictionaries may deviate vastly from industry jargon in various countries. Typically, governmental and standard documents steer clear of industry jargon. But when the official terms of one English speaking country vary from those of another for the identical item, which happens all the time, confusion can result. There are several such examples in this very document. This is why this page is very heavily linked to other pages from website of the translator, as well as other sources, in an attempt to increase comprehension and reduce confusion.

This comprehensive set of test procedures can be partly applied to non-intumescent materials as well. It is not exclusively intumescents, which may soffer degradation in adverse or even quite normal environmental conditions! Readers should consider the applicability of MATERIAL testing as a prelude to system testing in order to avoid the possibility of a host of conditions, which can render certain materials useless, which are not, however, currently included in system testing and certification schemes for passive fire protection materials qualified to procedures according to ULC-S115 and/or S101.

This procedure originated in the Federal Republic of Germany, where such testing of materials is mandatory within approval and certification procedures and systems approvals are not granted without materials approvals. Hence, by law, Germany clearly differentiates between building materials (for instance the caulking if a firestop system, on its own, would be a "material" of "Baustoff") and building components (the caulking, together with the packing and the penetrant and the fire separation would be a "component" or "Bauteil"). Each have separate requirements.

The expert committee (SVA = Sachverständigenausschuss "Brandverhalten von Bauteilen") in fact reserves the right to mandate further testing, in case the standard procedures are deemed inapplicable to certain materials. Typical products that are regularly tested and do require certification purely on the merits of material testing are all silicones (for B1 combustibility rating as per DIN4102) and mastic cable coatings (for intumescence).

The symbol "§" means paragraph.

Germans use the term intumescent. In German, it is spelled intumeszent. However, official government documents, such as the standard translated herein, don't use the word 'intumeszent'. Perhaps this is because the term itself is hard to find in common dictionaries or spell checkers, as opposed to manufacturers' literature and trade magazines. The original German document, upon which this English translation is based, utilises the term 'Dämmschichtbildner', which roughly (or directly) translates to "creator of a layer of insulation". This term, however, is not entirely descriptive of all intumescents, by definition, which may indeed swell and thus increase their volume and decrease their density. The term 'Dämmschichtbildner' is most applicable to thin film intumescents, which create a soft foam, which envelops a substrate as in spray applied fireproofing, or the interior of certain firestop pillows. However, the term is hardly descriptive of certain high strength, high pressure and lower volume intumescents, such as are used at times in plastic pipe firestop devices utilising sodium silicates and graphite. The latter intumescents, on their own, don't always create a uniform layer of insulation, which would not be defeated by convection. This is because they do not undergo a uniform bubbling process, or a 'liquid stage' and thus are also less endothermic. However, since ALL intumescents, high strength and low strength must be tested to this method (if they are to be marketed in Germany that is), the translation will use the term 'intumescent', as opposed to "creator of a layer of insulation", or the previous edition's version "materials that foam up under the influence of fire".

Also, the original document contains a variety of footnotes. Since this translation is written in html and the page formatting is not identical to any printed document, footnote texts are inserted with the main body of the text.

Also, there are many references to DIN4102. DIN4102 is a large, multi-component standard, which includes all German fire testing requirements, from combustibility, to flame-spread, fire-resistance ratings, as well as a catalogue (part 4) of "old" systems, using very common generic materials, such as concrete, home-made vermiculite plasters, steel, etc. Part 4 of DIN4102 is very similar to the appendix to the National Building Code of Canada, which depicts generic systems or designs for obtaining fire-resistance ratings, based on testing done at the National Research Council of Canada. As a result, Germans differentiate between "old" systems and "new" systems, whereby the "old" ones are listed in Part 4 of DIN4102 and the "new" ones would be those approved by DIBt. Obviously, the "old" ones do not require separate approval. Since generic materials are used, one must simply follow the printed directions in order to obtain a rating, very much like our National Building Code of Canada Appendix.

Also, Germans classify fire-resistance durations with alphanumerical designations. F90 = 90 minute fire-resistance rating, whereas T90 would be a 90 minute fire-protection rating for a fire door or S90 would be the same thing for a cable penetration firestop.

Also, while the original text utilises parentheses, whose contents bring clarity to the document, some information in parentheses is provided by the translator to clarify matters, which are obvious to insiders in the German passive fire protection market, but may be unclear or indeed misleading to outsiders. There are fundamental differences in the manner in which Germany approaches certification as well as approvals, compared to North America. It is noteworthy for the reader who is unfamiliar with this territory, to know the highlights of this process, as follows:

DIBt is an agency of the German federal government. In a way, DIBt is similar to a combination between ULC and SCC. DIBt writes standards, which are published in "communications" (=Mitteilungen), similar to the federal gazette, which publishes Canadian government laws, or the federal register, which publishes the proceedings of the US House of Representatives. DIBt also accredits testing laboratories, which are also government owned and operated, either by the federal or by their Provincial/State (Länder) governments. If a manufacturer desires to market a firestop or fireproofing product, he or she must run a test in a DIBt accredited laboratory. If he or she passes the test, the laboratory will automatically forward the results to the appropriate person at DIBt and thus apply for approval by DIBt. The basic system tests are actually run in accordance with DIN4102. DIBt differentiates between building materials (Baustoffe) and building components (Bauteile). If you pass a firestop test, that whole system is a building component. However, if part of that seal is intumescent, this then is classified as a building material. There are separate classifications of building materials, most notably in terms of combustibility and flame spread performance, all of which are determined by means of testing to DIN4102. Intumescence is seen as a characteristic utilised in building material classification. Building materials, whose function must be verified on a regular basis, are subject to a mandatory certification regime. Some building materials are exempted from this process, such as those which deemed A1 noncombustible per DIN4102, i.e. concrete, stone, etc. or "B3" easily ignitable as per DIN4102, such as polyurethane foam. Both of these extremes are common sense, really. If something is entirely inorganic and dead to begin with, why bother verifying the obvious at further expense? B3 on the other hand (easily ignitable) is not exactly a feather in anyone's cap to begin with. It is not a designation strived for by anyone, but something to avoid entirely. However, anything in between those two extremes, A1 and B3, including intumescents, contain a certain organic component, which is subject to deterioration under many influences. Thus, it stands to reason, that the use of such materials and the efficacy of such materials depends on the long-term performance and maintenance of its most basic properties. When such materials break down or are adversely affected by environmental influences, they can become the weak link in the chain that is the fire safety plan of an occupancy. Thus it is mandatory in the Federal Republic of Germany to engage in certification programs, which provide due diligence in terms of the efficacy of such materials beyond the one-time system test. DIBt will not issue an approval of any passive fire protection system, utilising such limited combustibility materials, without a separate building material approval. Both the building material (Baustoff) approval and the system approval (Bauteil) (be it a fire door gasket, a firestop or any such similar passive fire protection item) depend on the maintenance of positive periodic certification test results by a DIBt accredited governmental laboratory. In North America, our accreditation bodies (SCC and ANSI) have no such identical authority. Another large difference is that in Germany, chemical formulations and mix designs are not disclosed to the laboratory (as we do in North America - formulas are always part of the follow-up procedures disclosed to UL, ULC, WH, OPL and FM). Instead, in Germany, these formulas are disclosed exclusively to DIBt. DIBt embodies the quintessential, qualities of the incorruptible Prussian civil servant. Unlike North America, where it is not entirely unheard of to see laboratory personnel, with access to manufacturer formulations and process standards, who then leave the laboratory to work for private vendors (not that any country has a law against this, including Germany), whose product offerings may be enriched by the experience of the newly hired engineer, such instances are actually unheard of, when it comes to DIBt. DIBt enjoys an unsurpassed and unbroken trust. Hence German manufacturers are often reluctant to share formulations with North American laboratories (it is not their own government after all), which is expensive to avoid, when one desires to import products or manufacture locally under a certification program. Thus, German governmental certification programs, as administered by governmental laboratories, do involve factory audits. However, the procedures are limited to verification of physical characteristics of the building material (which indicate whether or not there may be a problem worthy of investigation). Typically, characteristics and simple physical tests are chosen, which have a direct impact on the performance of the product. Tolerances are set by DIBt, which form part of the DIBt material and/or system approval. For instance, DIBt approved spray applied fireproofing plasters are subject to bi-annual factory audits as well as laboratory bench-scale tests in the case of TU Braunschweig, a superb facility. If routine tests yield results, which fall outside of the DIBt tolerances, as set out in the approval text, such results are automatically submitted by the laboratory to DIBt, which then quickly cancels the approval. If a tendency is noticed in results, which shows a leaning towards one of the tolerance extremes, the laboratory will notify the manufacturer. DIBt approvals are always limited in duration and are re-considered (and re-invoiced) at the end of each approval duration period. By contrast, in North America, the laboratory, apart from FM, does not ever issue an approval for a system (Bauteil). The term approval is specific to an installed configuration in the field, which is bounded and which is acceptable to the AHJ. In other words, the local fire prevention officer or the local building inspector can approve plans or an installed fire door or closure etc. Whoever refers to an approval from ULC, ULI, WH or OPL, is mistaken. These laboratories cannot issue approvals. They issue listings, which are test results backed by a certification program. When a passive fire protection item is installed in the field, in a bounded fashion, this can then be approved by the AHJ (authority having jurisdiction). The exception is FM, which issues system approvals against insurance requirements, which have nothing to do with building code compliance. In Germany, however, approvals per se are required, just like listings are required in North America, for systems (Bauteile) and materials (Baustoffe) before they are even delivered to the jobsite. Both systems theoretically accomplish the same objectives. The German system achieves a greater level of assurance that confidentiality is maintained (which protects the interests of the manufacturer who desires that his or her products not become the technological basis for someone else's new products) and that the product will actually work. The North American system presumes that when the formula and the production standard are disclosed and monitored, that so long as I make the product identically to the one used in the system test, it will work for all time to come (as the environmental influences other than fire exposure, which can destroy products are simply excluded from the certain test regimes). However, this system may go awry, in the event of changes to raw materials, which may not be immediately apparent. There is also a gradient in the vigilance of follow-up test procedures from one lab to another in North America. Thus the North American user and the AHJ are bound by law to accept and presume that all is well, when in fact that may or may not be the case, particularly in complex organic products, such as intumescents, or endothermic products, except in the case of materials or systems, which are subject to testing, which includes environmental exposures, such as UL1709, which is a superb standard. Having said that, neither system is of course perfect. Insiders familiar wioth practices on both sides of the Atlantic can see where each could learn from the other, particularly if there were more flexibility in the basic legislative set-up concerning certification and field approvals.

Also, the reader (you) may get the impression that the German laboratories, who utilise this guideline, may be given a significant amount of latitude in terms of their potential abilities to deviate from from the procedures outlined in this document if warranted due to particular product characteristics, which may make strict adherence to this standard impractical or result in unreliable data. One must, however, bear in mind, that a report from a DIBt accredited laboratory only forms the basis for an application for approval by DIBt. In fact, the bottom of the report contains a mandatory and cautionary statement, indicating that the sole purpose of the report is to provide data to supplement an application for approval by DIBt. The report thus has no validity in the field minus an accompanying and current DIBt approval. Once this request is received by DIBt, there is still the matter of convincing the SVA expert committee (which meets several times per year in Berlin) that what was done is proper and worthy of the approval. The translator has seen one case, where field data was submitted to DIBt, in connection with a delamination issue of a spray applied fireproofing. DIBt almost immediately imposed further restrictions on the vendor's approval to account for what had been found in the field and did not revert the approval back to the original state until sufficient data had been produced to prove beyond the shadow of a doubt that the problem was inadequate surface preparation (oily substrate), preventing a proper bond, thus acquitting the product.

|

from the work of expert committees (SVA) |

|

SVA "Fire Behaviour of Building Components" |

Chairman: Minister Councillor Temme

Secretary: Mrs. Herzog

A task group within the SVA "Fire Behaviour of Building Components" has established approval guidelines for intumescent building materials, which are now mandatory and available in the form of the November 1996 Edition (which was published in the DIBt Mitteilungen January 1998). These guidelines supersede the "Guideline of Test of Building Materials that foam up under the influence of fire" (dated September 1988).

Intumescent building materials are building materials utilised in structural fire protection, which become effective when exposed to elevated temperatures during a fire by means of foaming up. Through the use of these building materials, the fire behaviour and/or fire-resistance of building components or items can be improved and/or ensured. These building materials are supplied and utilised in the following forms:

-boards, strips, foils

-fabrics

-putties, pastes, mastics

-coatings.

Such building materials are used, among others, in the following applications: building joints, cable penetrations, pipe penetrations in wall and floor assemblies required to have a fire-resistance rating as well as to provide circuit integrity of electrical cables during a fire. In the process of (DIBt) approval procedures, the characteristics of the building material, whose long-term fire protection efficacy must be proven, as well as its behaviour against environmental influences are determined.

The approval guideline describes tests of the building materials, as they relate to their intended (environmental) application, which form the basis for the judgment of approvability. The approval guidelines are printed in the official body of this document.

|

Official Part |

Approval Guidelines for Intumescent Building Materials

November 1996 Edition

|

1 APPLICABILITY |

1.1 These approval guidelines apply to testing of intumescent building materials used in structural fire protection, hereinafter 'building material', which form the basis of (DIBt) approvals for certified systems (used in passive fire protection).

These approval guidelines do not contain tolerances with regards to the characteristics of the building materials.

1.2 These approval guidelines do not apply to testing of intumescent fire retardants for timber, which is used to obtain a B2 building materials classification as per DIN4102 (In North America, we use the Steiner tunnel test for this, in order to obtain a flame spread rating). These approval guidelines also do not apply to testing to obtain a fire-resistance rating for structural steel (Canadians use ULC-S101, the US reference ASTM-E119). The procedure applicable to testing intumescent fireproofing materials for structural steel is is: "Guidelines for Test and Approval of Intumescent Fire Protection Coatings for Structural Steel" (Note: This referenced procedure has been replaced by DIBt. The new procedure for testing reactive spray fireproofing can be seen under this link: http://www.oocities.org/ghering2000/dibt2.html.)

|

2 DEFINITIONS AND EXPLANATIONS |

2.1 Intumescent building materials are building materials utilised in structural fire protection, which become effective when exposed to elevated temperatures during a fire by means of foaming up.

These building materials and accessory building materials are supplied and utilised in the following forms:

-boards, strips, foils

-fabrics

-putties, pastes, mastics

-coatings.

Such building materials are used, among others, in the following applications: building joints, cable penetrations, pipe penetrations in wall and floor assemblies required to have a fire-resistance rating as well as to provide circuit integrity of electrical cables during a fire.

2.2 The foam height (in mm) (Foam height refers to the amount of intumesced char or the quantification of volume increase.) shall be that which is determined by taking the middle of the maximum and minimum readings of results from exposing samples to the elevated temperatures within a duration of five (5) minutes.

2.3 The expansion pressure (in N/mm²) shall be that which is measured in the test apparatus as per Appendix 6.

2.4 "Liquification" is a liquid phase of the building material prior to foaming up (intumescing) within a certain temperature range.

|

3 GENERAL |

3.1 These building materials may be used

- in building components as closures and firestops,

- on building components for surface protection,

- between building components as building joint firestops. (This reference to the use of these building materials as building joint firestops is understood for the purpose of these approval guidelines to mean that the building materials be used as components in the construction of bounded building joint firestop assemblies. Further testing beyond these approval guidelines is required to qualify the use of these building materials as building joint firestops or components thereof.)

for fire protection purposes, provided that the adjacent building components meet the requirements of the applicable fire-resistance ratings.

These building materials are classified in accordance with the intended application, as well as the environmental exposures, which are applicable to each such application, as follows:

3.2 Building materials, which are used inside of buildings. In this application, building materials may be subject to short-term exposures of gaseous chemicals. Exposures of the building materials, beyond that, which generally occurs in rooms utilised as residential quarters or storage facilities are not mandatory in this category. (Important Note: It is customary in Canada for firestops to be installed before the building's exterior walls and windows are installed. This often leads to weather exposures for the firestops during construction. This has led to firestop failures both in Toronto, ON and in Vancouver, BC. The materials were tagged "interior exposures only" and used because of very low cost. Building materials may have to be exterior grade to survive the construction period.)

3.3 Building materials, which are used inside of buildings where special exposures are expected. This includes wet rooms or comparable areas, which are subject to an elevated relative humidity (this does not, however, include direct wetness, such as water condensate, which will not evaporate) and/or rooms, which are subject to limited duration and pre-determined exposures of chemicals (e.g. solvents).

3.4 These approval guidelines are applicable only to those building materials, which are used in applications and locations, where they are otherwise protected from direct weather exposures.

In the event that these building materials are used in applications and locations, where they are directly subjected to weather exposures such as strong, heavy rain, freeze and thaw cycling and ultraviolet radiation (sunshine), further testing must be mandatory, in consultation with the (DIBt accredited) testing laboratory, as per §4.

|

4 PROOF |

4.1 General

These building materials must be used in practice in the (permanent) environments for which testing according to these approval guidelines has qualified them for. The detailed formulations and mix designs of these building materials must be submitted to the German Institute for Building Technology. Additionally, the identifying characteristics of these building materials shall be determined in accordance with procedures on file with the German Institute for Building Technology. The following shall be utilised for proof.

The execution of separate specific tests may not be required, if, in the experience of the (DIBt accredited) test laboratory or the manufacturer, a building material does not possess any of the given characteristics (see §4.2) or resistance to environmental exposures (see §4.3) or when certain specific tests are inapplicable to the intended use. If the chemical composition of any such building material is such that it will not have a detrimental or deleterious effect upon other (adjacent) building materials (see §4.4).

If a building material may be utilised in several variants, the scope of testing may be reduced such that the full test program may be carried out only on the basic version of the building material, whereas additional parts of the test program are executed upon the variants where deviations are to be expected. The extent of the reduction of the test protocol shall be decided upon jointly with the (DIBt accredited) test laboratory.

Building materials, which, for example may be used as an outer protective layer to guard against the effects of environmental influences, shall be used to envelop the applicable samples and then exposed to all tests from §5.2 through §5.4.

In the event that a building material is intended to be used in applications such as direct weather exposure, constant direct wetness, or exposures to chemicals, additional testing shall be required. For this purpose, additional tests may be agreed upon in conjunction with the (DIBt accredited) test laboratory.

4.2 Basic Tests

4.2.1 The thickness of boards, strips, foils and fabrics shall be determined in accordance with §5.2.1

4.2.2 The surface mass of boards, strips, foils and fabrics shall be determined in accordance with §5.2.2

4.2.3 The density of mortars, putties, pastes, mastics and coatings, as supplied by the manufacturer, shall be determined in accordance with §5.2.3

4.2.4 The contents of non-escaping ingredients for mortars, putties, pastes, mastics and coatings, as supplied by the manufacturer, shall be determined in accordance with §5.2.4

4.2.5 The mass reduction, which occurs as a result of heat exposure, shall be determined for all building materials in accordance with §5.2.5.

4.2.6 The foam height for all building materials, is to be determined in accordance with §5.2.6

4.2.7 The expansion pressure, where applicable, is to be determined in accordance with §5.2.7.

4.2.8 The building material class, as per DIN4102-1 ("Fire Behaviour of Building Materials and Building Components; Building Materials; Definitions, Requirements and Tests") shall be determined as per §5.2.8. The building materials must, at a minimum, meet the requirements of normal combustibility (Building Material Class DIN4102-B2).

4.2.9 A determination shall be made in accordance with §5.2.9 whether or not the building material traverses a "liquification" phase.

4.2.10 The density of the enveloping protective layer shall be determined in accordance with §5.2.10.

4.3 Test of Building Material Behaviour under Environmental Influences

4.3.1 The building materials' measured foam height (see §4.2.6) and expansion pressure (see §4.2.7) must not substantially change during the intended duration of practical use inside and/or around the outside of building components, whose fire resistive efficacy they are contributing to, under the environmental influences, which are expected in the occupancy in which they are located.

4.3.2 The building materials shall be subjected to weather exposures in accordance with §5.3.2 in order to determine the influence of moisture.

For exposures which exceed those expected for normal storage and residential functions, applicable exposures in accordance with §5.3.3 (water condensate exposure) may be tested.

4.3.3 The building materials shall be subjected to elevated temperature exposures in accordance with §5.3.4 in order to determine the influence of heat (such as from the heat resulting from the ampacity of energized cables).

4.3.4 The building materials shall be subjected to a variety of chemicals (paints, solvents, oil, etc.) in accordance with §5.3.5 in order to determine the influence of occasional, short-term exposures to such substances.

4.3.5 In the event that the building materials can be negatively affected due to their composition and/or particular use by conditions other than those outlined in paragraphs 4.3.2 through 4.3.4, further tests relevant to their individual behaviour versus the expected specific environmental exposures may be mandated.

4.4 Effect of the Building Materials on other (adjacent) Building Materials

The building materials must not have a deleterious effect upon other building materials (plastic for example), with which they come in planned contact (i.e. through bounding in a DIBt system approval or certification listing in North American terms). In the event that the building materials may have an unlawful, deleterious effect upon building materials other than those investigated in accordance with §5.4, whereby contact between the respective materials is planned, and/or expected in practice, further testing shall be required to ascertain long-term bounding.

|

5 TEST PROCEDURES |

5.1 Sample Preparation

All samples intended for testing in accordance with §5, with the exception of samples intended for tests in accordance with paragraphs 5.2.3 through 5.2.4 shall be stored until mass equilibrium has been achieved in normal climatic conditions in accordance with the provisions of DIN50014-23/50-2 "Climates and their technical Application; Normal Climatic Conditions".

5.2 Procedures for Basic Tests

5.2.1 The thickness of the building materials shall be determined

- for boards, foils and fabrics on samples sized 10cm x 10cm or samples sized in accordance with §5.2.7

- for strips on samples of 50cm length

in 5 locations per sample with a contact measurement device of 10mm diameter.

5.2.2 The surface mass of samples supplied in the form of boards, strips, foils and fabrics shall be determined by means of weighing of the samples, which shall be sized in accordance with §5.2.1.

5.2.3 The density of samples supplied in the form of mortars, putties, mastics and coatings shall be determined on samples of 100cm³ in accordance with the provisions of DIN53217-2 "Lacquers, Paints and other Coatings".

5.2.4 The determination of the contents of non escaping ingredients shall be made in accordance with the provisions of DIN53216-1 ("Determination of non-escaping Contents; Procedures for elevated Temperatures for Resins, Resin-Solutions, Lacquers, Paints and other Coatings") over a period of three (3) hours at a temperature of 105°C.

5.2.5 The loss of mass of samples as a result of exposure to elevated temperatures shall be determined in accordance with the provisions of Appendix 2, in the form of percentage mass loss between sample mass before testing and the resulting sample mass as measured after the cooling off period, which follows the heat exposure.

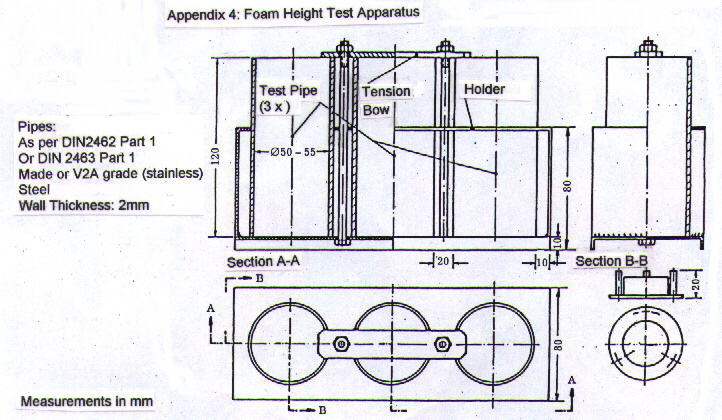

5.2.6 The maximum foam height shall be determined for each of 6 samples (50mm diameter each - Sample diameters are approximately 2mm smaller than the inside diameter of the test pipe used for this purpose.). The samples shall be placed in a test apparatus conforming to Appendix 4. The test apparatus containing the sample shall be placed in a pre-heated oven for a duration of 30 minutes. (Strips of widths < 50mm shall be tested accordingly.) The test shall be performed in accordance with the provisions of Appendix 3.

For the determination of the maximum foam height, the maximum and minimum foam height of each sample shall be measured and recorded. The foam height resulting from the testing of these 6 samples shall be the average of all of the aforementioned measured sample foam height values.

In the event that it is impossible to accurately determine the maximum foam height in accordance with the procedures outlined in Appendix 3, it shall be permissible, with the agreement of the (DIBt accredited) laboratory, to conduct other tests, as deemed appropriate for the building material. Other tests may include free-foaming or variations in the test duration or temperatures.

5.2.7 The expansion pressure shall be determined via the use of an apparatus conforming to Appendix 6, utilising 10 samples. The test shall be run in accordance with the provisions of Appendix 5.

The results from these tests shall be recorded in terms of maximum expansion pressure (in N/mm²) as well as the time necessary to reach the maximum expansion pressure.

In the event that it is impossible to accurately determine the maximum expansion pressure in accordance with the procedures outlined in Appendix 5, it shall be permissible, with the agreement of the (DIBt accredited) laboratory, to conduct other tests, as deemed appropriate for the building material. Other tests may include variations in the test duration or temperatures or sample sizes.

5.2.8 The characteristic "normal ignitability" (class B2) shall be determined in accordance with the provisions of §6.2 of the standard DIN4102-1 ("Fire Behaviour of Building Materials and Building Components; Building Materials; Definitions, Requirements and Tests" - B2 test).

If necessary (in the event the building materials are less flammable than B2 as per DIN4102-1), the characteristics shall be determined via testing in accordance with the latest versions of the following standards: "non-combustible" or "difficult to ignite" as per "Approval Guidelines for the Determination of Non-combustibility of Building Materials (Building Material Class A in accordance with DIN4102-1, or, respectively, "Approval Guidelines for the Determination of Poor Ignitability of Building Materials (Building Material Class DIN4102 - B1).

5.2.9 The applicability of the characteristic "liquification" of a building material shall be determined via testing of samples sized 2mm thick x 50mm diameter. The samples shall be exposed to temperatures of 150°C, 200°C, 250°C, 300°C.

5.2.10 The efficacy of protective coatings shall be determined as follows:

- Testing of CO2 permeability shall be conducted in accordance with DIN53 380 "Test of Plastic Foils; Determination of Gas Permeability".

- For the determination of the impermeability of a protective coating coated samples are placed inside a closed container, such as a piece of pipe filled with water (for example length: 1.5m, diameter: 0.1m), which is equipped with a vacuum pump, will be subjected to a lower the internal pressure.

An absolute pressure of <15mbar shall be maintained for 1 minute. During this low pressure phase, watch for air bubbles emanating from the coated samples.

5.3 Procedures for Tests of the Behaviour under Environmental Influences

5.3.1 Sample construction

The construction of the samples shall follow the manufacturer's installation instructions for each building material.

For the purpose of these tests, building material sample quantities and sizes shall conform to Appendix 1 (Test Plan).

5.3.2 Short Duration Tests (accelerated exposures)

A minimum of 2 samples of diameters sized in conformance with paragraphs 5.2.6 and 5.2.7 shall be oriented vertically and stored for a duration of 4 hours at 0°C followed by 4 hours at +20°C, at a relative humidity of 80%, followed by 16 hours at +40°C and 50% relative humidity. This test cycle shall be maintained for a period of 21 days without interruption.

5.3.3 Behaviour during Water Condensate Exposure

These tests shall be performed in the event that the corresponding exposure of the building material can be expected in the practical use of installed field configurations.

A minimum of 2 samples of diameters sized in conformance with paragraphs 5.2.6 and 5.2.7 shall be exposed to a changing condensate water climate in accordance with DIN50017 "Climates and their technical Applications; Water Condensate Test Climate" (Test Climate DIN50017 - KFW) (Translator's Note: An English copy of the referenced DIN standard was not available to the translator at the time of translation. The acronym "KFW" thus has a German meaning and users of this procedure are cautioned to check the original German version of said standard to ascertain use of the correct provisions of the test.) for a duration of 15 days. (This test includes the test outlined in §5.3.2)

5.3.4 Behaviour during Exposure to elevated Temperatures

A minimum of 2 samples of diameters sized in conformance with paragraphs 5.2.6 and 5.2.7 shall be placed in an airtight conditioning chamber at a temperature of +80°C (with the agreement of the DIBt accredited laboratory, this temperature may be substituted with either +60°C or +40°C) for a duration of 40 days.

5.3.5 Behaviour during occasional, short-term Exposures to Chemicals

5.3.5.1 Coatings

A minimum of 2 samples of diameters sized in conformance with paragraphs 5.2.6 and 5.2.7 shall be coated with a single layer of pigmented protective coatings of the following types:

- a plastic dispersion (on a PVAC basis),

-an alkaline resin,

-a polyurethane acrylic coating,

-an epoxy resin (standard trade grade).

Following this, the coatings on the samples shall be allowed to cure for a duration of 4 weeks in normal climatic conditions as per DIN50014-23/50-2 "Climates and their technical Application; Normal Climatic Conditions".

5.3.5.2 Solvents/Oil

These tests shall be performed in the event that the corresponding exposure of the building material can be expected in the practical use of installed field configurations.

A minimum of 2 samples of diameters sized in conformance with paragraphs 5.2.6 and 5.2.7 shall be immersed for a period of 2 minutes in the following solvents:

-butyl acetate (ester) (98/100%)

-heating oil EL,

-butanol (alcohol)

-test benzene (aliphatic hydrocarbon), (boiling point range 140-180°C)

Following this exposure, samples shall be stored until mass equilibrium has been achieved in normal climatic conditions as per DIN50014-23/50-2 "Climates and their technical Application; Normal Climatic Conditions".

5.3.6 Evaluation and further Tests of the exposed Samples

5.3.6.1 A visual comparison of the exposed versus unexposed building material samples shall be made. The influence of the exposures in accordance with paragraphs 5.3.2 through 5.3.5 shall be made in terms of the outer appearance of the samples. Changes in appearance, which may be deemed to have an influence in terms of reducing the efficacy of the building materials (for example efflorescence, surface degradations due to evaporation of internal moisture, dissolving effects, shape- and colour changes) shall be noted.

5.3.6.2 Sample measurements shall be taken by means of suitable contact measurement devices in accordance with the provisions of §5.2.1 before and after each of the exposures outlined in paragraphs 5.3.2 through 5.3.5.

Any dimensional changes shall be reported in terms of percentage.

5.3.6.3 The determination of sample area mass for strips, foils and fabrics shall be made before and after each exposure in accordance with the provisions of §5.2.2.

5.3.6.4 The determination of changes in sample mass for mortars, putties, pastes, mastics and coatings shall be made by means of measurements and weighing before and after each exposure.

5.3.6.5 The determination of foam height of all exposed samples shall be made in accordance with §5.2.6.

5.3.6.6 The determination of expansion pressure of all exposed samples, for all building materials, shall be made in accordance with the provisions of §5.2.7.

5.4 Procedures for Tests of the Influence upon other Building Materials

5.4.1 Sample Construction

The construction of the samples shall follow the manufacturer's installation instructions for each building material.

The contact building material must be coated on one side with the (intumescent) building material, which is being investigated. For rigid, or semi-rigid materials, suitable means shall be utilised to apply such pressure between the two items, that a direct contact shall result.

A minimum of 2 samples of each contact building material shall be fabricated and used for testing hereunder.

5.4.2 Contact Building Materials

Samples sized 150mm x 40mm shall be fabricated from polyvinylchloride (PVC) and polyethylene (PE)

(Translator's Note: One may be surprised that the only contact materials being tested here are plastic. However, upon close examination, the only intumescents that have really done harm to any adjacent products have dissolved or attacked plastic, such as plastic pipe or cable jacketing, when the intumescent sealant contained a strong solvent, which, by now, the manufacturer has replaced about 1 decade ago. Apart from that, water based products may cause mild steel to rust - but who would leave exposed mild steel and not expect rust? Even alkaline mortars have been placed directly against aluminum cable trays but the resulting oxidation has never caused a real problem anywhere, particularly since trays are never mounted such as to count on the structural integrity of the seal to support the cable trays during normal operation.)

5.4.3 Test Procedures

5.4.3.1 Samples fabricated in conformance with §5.4.2 shall be stored for a contact duration of 40 days in normal climatic conditions as per DIN50014-23/50-2 "Climates and their technical Application; Normal Climatic Conditions".

5.4.3.2 For all samples conforming to §5.4.2, following the contact period, the coating shall be removed and the contact building material shall be examined in accordance with the provisions of §5.2.6.1.

5.4.3.3 For samples conforming to §5.4.2.2, following the contact period, the coating shall be removed and pull tests shall be performed in accordance with DIN53455 "Tests of Plastics; Pull Test".

5.4.3.4 The results shall be compared with the results of unexposed samples.

5.5 General Test Guidelines

5.5.1 All tests conforming to paragraphs 5.2 through 5.4 shall be conducted with building materials of the same type or composition.

5.5.2 The measured foam height results obtained from testing conforming to §5.2.6 and the expansion pressure results obtained from testing in accordance with §5.2.7 shall be evaluated.

5.5.3 In the event that the provisions of this approval guideline are intended to be deviated from, due to special product characteristics, prior agreement shall be reached (on the subject matter between the manufacturer and the DIBt accredited laboratory).

5.5.4 For the determination of the building materials' behaviour under environmental influences, the short-term exposure tests conforming to §5.3 shall be supplemented by long-term testing of the samples, which shall be stored for durations of 2, 5 and 10 years.

A total of six samples, conforming to Appendix 1, shall be stored in a room, which is well ventilated, unheated, and protected from rain and sunlight. For each set of tests, 2 samples shall be removed from storage and subjected to the test regime outlined under §5.3.6 following their respective storage durations of 2, 5 and 10 years.

Further mandatory test provisions (for certification or follow-up purposes) shall be included in the requirements of each specific (DIBt) approval.

5.6 Test Plan

5.6.1 Proof (results) must be provided in accordance with paragraphs 4.2 through 4.4.

5.6.2 For building materials conforming to §3.2, the following tests must be conducted:

- basic tests in accordance with paragraphs 4.2.1 through 4.2.9

- weather exposures in accordance with §5.3.2

- behaviour under the influence of elevated temperatures, in accordance with §5.3.4

- behaviour against paints, in accordance with §5.3.5.1

- influence upon other building materials in accordance with §5.4

For building materials conforming to §3.3, the following tests must be conducted:

- basic tests in accordance with paragraphs 4.2.1 through 4.2.9

- condensate water exposure in accordance with §5.3.3

- behaviour under the influence of elevated temperatures, in accordance with §5.3.4

- behaviour against paints, in accordance with §5.3.5.1

- influence upon other building materials in accordance with §5.4

5.6.3 The required tests and their respective minimum sample quantities are summarised in Appendix 1.

5.7 Conclusions and Evaluation of the Test Results

5.7.1 Test results from testing in conformance with paragraphs 4.2, 4.3 and 4.4 shall be evaluated such as to ascertain whether or not the characteristics of the building materials are substantially changed through exposure to environmental influences and whether or not the building material has a damaging effect upon other building materials.

Observations concerning a possible liquification of the building material, when subjected to rising temperatures, shall be recorded.

The type and consistency (for example: porosity) of the foamed (intumesced) material shall be described.

The results from testing in accordance with §4.2 shall be compared with those gained from prior testing to paragraphs 4.3 and 4.4.

The (DIBt accredited) laboratory shall decide whether deviations are of significance and shall thus make a recommendation in the test report.

|

6 Test Report |

Testing in accordance with the provisions of §5 shall be recorded by the (DIBt accredited) laboratory in the form of a test report, which includes all test results, descriptions of the samples and the test set-up as well as the observations during the test (in a standardised format).

In particular, during the determinations of foam height

- the foam height / the foaming factor

- the sample thickness

- the test temperature

- the test duration

- the area pressure and

during the determination of the expansion pressure

- the expansion pressure

as well as

- the combustibility of the building material (classification in accordance with DIN4102-1 ("Fire Behaviour of Building Materials and Building Components; Building Materials; Definitions, Requirements and Tests")

- the temperature range within which the building material liquifies

as well as any deviation from the standard test protocol shall be recorded.

The (DIBt accredited) test laboratory shall make a recommendation concerning the suitability of the building material for the issuance of a building controls (DIBt) approval.

|

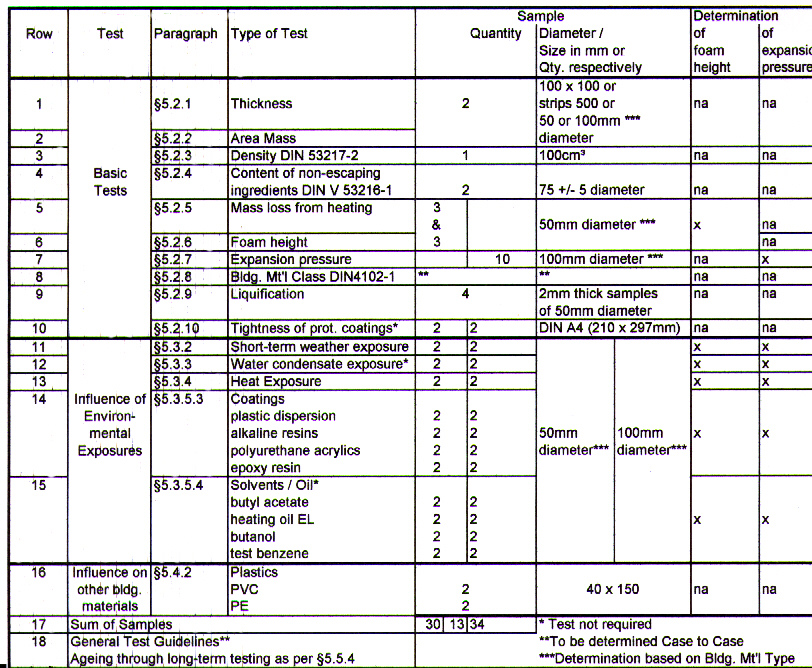

Appendix 1: Test Plan |

|

Appendix 2: Test Procedures for Determination of Mass Loss due to Heat Exposure |

The muffle oven to be used for this procedure must be capable of being adjusted for and holding a minimum temperature of 800°C. Prior to the test, the oven shall be pre-heated to the desired test temperature. This temperature level shall be held for a minimum duration of 60 minutes.

Testing shall be conducted on 3 samples for an identical duration and at an identical temperature in conformance with the provisions of §5.2.6.

The material shall be placed in a bowl, which consists of inert material, aluminum, for example. The quantity of material to be tested is chosen such that it will not foam beyond the confines of the bowl.

Following the test, the sample and the bowl shall be stored until a mass equilibrium has been achieved in a container, which excludes the presence of airborne moisture (exicator). Following this, the mass shall be determined.

For the purpose of this material test, existing protective foils shall be removed. Existing coatings shall be considered.

|

Appendix 3: Foam Height Test Procedures |

Test Procedure

The muffle oven to be used for this procedure must be capable of being adjusted for and holding a minimum temperature of 800°C. Prior to the test, the oven shall be pre-heated to the desired test temperature. This temperature level shall be held for a minimum duration of 60 minutes.

In the event that the building material is manufactured in various thicknesses or densities, the lowest and highest thicknesses and/or densities shall be tested. Pastes, mortars, putties and mastics shall be tested at a thickness of 5mm and coatings shall be tested at a thickness of 3mm (on aluminum foil).

If appropriate, the sample thickness shall be reduced such that the foam height does not exceed the maximum measuring height of the test apparatus (Appendix 4).

The samples, along with the test apparatus (Appendix 4), shall be placed in the oven within 10 seconds. This will cause a temporary temperature reduction in the oven. In the event that several samples are located inside the oven at the same time, all samples shall be placed beside one another, at the same elevation inside of the oven.

The test duration is ordinarily 30 minute. The foam height is determined within 5 minutes of sample removal from the oven.

Test Temperature

In preliminary tests, the required test temperature for the determination of the maximum foam height shall be determined. In order to find the appropriate test temperature of a product, the oven temperature is raised in increments. The final test temperature shall be established within a tolerance of 50K.

Once the test temperature has been determined, all foam height tests shall be conducted at that specified temperature.

Determination of Foam Height

For tests with weight application, the height of the lower edge of the weight shall be equal to the foam height.

For tests without weight application, the lowest and highest points on the surface shall be measured. The calculated average of the two represents the foam height. Voids within the interior of the foamed (intumesced) samples shall not be considered.

|

Appendix 4: Foam Height Test Apparatus |

|

Appendix 5: Expansion Pressure Test Procedures |

1 General

For measuring expansion pressure, a sample is placed between two pieces of aluminum foil of 50µm thickness inside of the test apparatus conforming to Appendix 6.

For materials, which are subject to liquification and thus flow out the side, the samples may also be bound within a stainless steel ring to prevent material escape.

Generally, the intumescent building materials shall be tested in the lowest as well as highest application thickness. Pastes, mortars, mastics and putties shall be tested at a maximum thickness of 5mm. In the latter case (if supplied in varying densities), the lowest and highest density versions of each building material shall be tested.

2 Sample Preparation

Utilising the intumescent building material intended to be tested, a sample of a diameter d of 50mm </- d </- 113mm shall be constructed. The tolerance shall be +0 / -2mm. The sample thickness shall be measured with a suitable contact measuring device (0.1mm graduated) in four (4) spots, which are located at 90° to one another, 10mm from the edge and in the middle. The average shall be calculated from the results.

For materials which are bound within a metal ring (for test purposes, as outlined above), the mass of the sample shall also be determined.

3 Test Procedure

3.1 Test without side borders

(Procedure A)

The sample shall be centrally placed between the two aluminum foils and then inserted into the apparatus.

3.2 Test with side borders

(Procedure B)

The samples shall be placed inside of appropriately sized steel rings, in accordance with #2 above.

The steel ring, which shall consist of stainless steel, has an inside diameter conforming to #2 above with a tolerance of +0.2mm / -0mm.

Preferably, steel rings of 4mm and 9mm height shall be used (tolerance 0.1mm). The sample thickness shall not exceed 5mm and 10mm, respectively.

The sample shall be centrally placed between the two aluminum foils and then inserted into the apparatus.

3.3 Test Apparatus Preparation

In the ZERO position of the hot plates (gap 0mm) there shall be a preliminary pressure of approximately 60N. The gap between the hotplates, which is required for the performance of the test, shall be adjusted in the measuring apparatus via the graduation.

When testing samples, which are placed inside of a steel ring, the heating plates shall be moved into a position such that the gap between them is 1mm larger then the height of the steel ring.

3.4 Measuring of the Expansion Pressure and Evaluation of the Results

The expansion pressure (N/mm²) shall be continuously recorded in a suitable registration apparatus (data logger). Until the maximum pressure has obviously been reached or exceeded, the test runs duration is no longer than 10 minutes.

The test report shall reflect the maximum expansion pressure.

The test report shall further indicate whether procedure A or procedure B has been used to obtain the results.

For intumescent building materials, which have been tested to procedure B, a reference curve may be established about the relationship between the expansion pressure of the sample material, which remains within the steel ring. This curve shall consist of a minimum of 5 basis points. Each measuring point shall be verified by no less than two measurements.

|

Appendix 6: Expansion Pressure Test Apparatus |

Brief Description of the EXPANSION PRESSURE Measuring Apparatus

The measuring device for the determination of the expansion force resulting from the prescribed heat exposure of an intumescing material is mounted within a frame, which consists of a base plate (1), two columns (2) and a pressure plate (3).

The upper pressure plate, which remains static during the test, is connected with the frame via a cover plate (4), which may be swung outward for cleaning purposes via a guidance system (5, 6, 6a, 7). For rapid placement of sample sheets, there is a lever (8/9) for the cover plate, which may be used to effect a change in height of 15mm.

The lower pressure plate conveys the force, which is generated as a result of the test, via a transfer apparatus to the force receiver, which is mounted on the base plate.

The (force) transfer apparatus is equipped with an adjustment wheel (11) and permits sample thicknesses of up to 32mm inside of the working room.

The spindle (10) is used for locking purposes.

Caution: When testing samples, which are placed inside of a steel ring, the heating plates shall be moved into a position such that the gap between them is 1mm larger then the height of the steel ring.

END OF TRANSLATION

Achim Hering, 05. February 2001, Capreol, ON, Canada

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|