WATER as FUEL - WATERFUEL - WATERCAR - WATERGAS - WATERBURNER - WATER FIRE - WATERPOWER - WATERBREAKER - WATERERA - WATERMOTOR - WATERENERGY -

---------------------------------------------

Home -Introduction -Conclusion -Site Map - Links

Water Electrolysis Systems - Water Explosion Systems - Water Plasma Systems - Other Water Dissociation Systems - Other Systems

---------------------------------------------

Electrolysis menu : CARS - LORRIES/GENERATORS - WELDING - HYSTORY and PATENTS - TRICKS - OWN REALIZATION

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - May be the SIMPLEST and FASTEST WAY TO GET AN HYDROXY GENERATOR in your CAR :

1. Just buy and install a Brown Gas welding machine, 220V - 400W ; 120L/hour, (for 300 USD here in Asia (products made in China)).

2. buy and install an inverter to run the Brown machine from the battery, inverter 12V-220V, 400W,( for 130 USD here in Asia).

3. install if needed a powerful enough alternator on the car ; 400W/13V=30-35A, alternator 60A (for 70 USD installed, here in Asia). total cost : USD 500

Procedure : install the alternator, connect the inverter, then the Brown machine to the inverter, put it in the boot, and install a pipe that bring the gas to the carburetor… simple !

Brown Gas Welding machine are sold since 20 years, all over the world, mainly produced in China and Korea, there is also Us models ; the advantages to use a commercial version of Hydroxy Electrolyser is that it is of improved manufacture, safe and of good quality, including all details like overpressure, power limiter and indicator, high efficiency, auto fan cooling, etc…

A good Brown Gas machine (3 Watt/hour per liter of gas) is very efficient .

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - Or you'll have to build it yourself; Many examples of realizations can be found on the web, especially on forums ;

Majority concern basic concept of puting 2 or more rods or plates in a container with pipe water inside, connected on the car's battery;

it makes gas, it can save fuel on your car, but it has many dis-advantages and so it won't stand long time.

# - See some pictures of home-made ELECTROLYSERS for cars, from internet websites and forums :

Main problems are HEAT that bring the water to boil and escape very fast from the container, and creating high dangers of burning/explosion.

An other problem is that plastic containers, simple to use, are not strong enough to handdle an gas explosion, due to very rare 'back-fire' (flame in the carburetor that ignite the gas, and goes back to the electrolyser), so it's dangerous; the only safe material for electrolyser is METAL.

And if you use pipe or mineral or sea water it wil help to oxydise the metallic plates and eat them.

Also many electrolytic complement/catalysts are toxic, see the dedicated page TRICKS (read it properly before starting in this field, it could save your life...).

To resume, by experience, I suggest you to use SERIE CELL design, Stainless Steel Plates for electrodes, and Iron or SS 16 Gauge minimum for the containers, distilled/dionized water+ Sodium Hydroxide for the electrolyte...

You'll be sure to end up with a cheap, simple to build, robust, safe and very efficient electrolyzer.

It's what I do for myself and friends, and we get interesting fuel saving, from average 35% to 65%, depending on cars and use.

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

--------------------------------------------- Return to the top

# - Tero.ranta electrolyser 'series cell' experimentation and success :

He made a PDF file about how to realize a 'series cell' electrolyser, for high efficiency gas production :

Tero's set up to successfully run a small engine from Brown Gas ONLY : videos on the web :

--------------------------------------------- Return to the top

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

# - MY OWN STORY OF EXPERIMENT and REALIZATION OF HYDROXY GENERATORS for CARS, in Asia:

M.D.G. 2005-06 and friends experiments : details of our failures and successes :

Some of the last WORD drawings I made for the workshop to build it.

After studying the subject for hundred hours, we started to experiment;

Of course we started by what was looking the simplest to save fuel on a car ; we had choice between Pantone reactor, Water Explosion or Hydroxy generator, being the simplest for beginners like us, we decided just to put two pieces of Stainless Steel in water, hooking them to the Chemelec diagram for pulsed frequencies, thinking that it was essential for electrolysis and hydroxy…

After few days the electronic was no more than 'a hope to get one day an extra-ordinary production of gas', and used to look at the creation of white powder coming out of the Electrodes...What is it, Where it comes from ?!?

We discovered that the straight 12V from the battery was giving more gas, through more Amps.

We tried many kind of electrolytes, some could have killed us, but I found warnings on the net, at oupower.com essentially that saved us. Chlorine and salt will give DEADLY chlorine gas, and Baking Powder (Bicarbonate) will give away also DEADLY Carbon Monoxide, so NEVER use these 3 items with the water for electrolysis purpose !

Pipe water, rain water, Reverse Osmosis water … the best and the ONLY ONE that make no problem is distilled water + Sodium Hydroxide ! (very easy and cheap to buy LYE / Sodium Hydroxy)

All other water mixes give red deposit, and tend to eat the electrodes, a lot of troubles.

We tried all kind of forms for the electrodes, pipes tubes, square tubes, plane plates, rods, etc…

Using pipes, like in Meyer design, we discovered the powerful explosion of Hydroxy; the little shaking of one of the plastic container make a tube rubber separator fall down, and the tubes coming too close from another, a spark occurred that ignited the gas in formation in the water and the chain reaction made the plastic box explode in pieces next to my friend's arm, letting him a lot of bloody marks.

Be very careful with Hydroxy, because it is a very explosive gas !

Then we discovered that more than 16Gauge thick Iron pipes can resist to the explosion of Hydroxy, like those the demonstrator use in Brown Gas Denis Lee shows, it implodes = no more danger !

And of course we use 2 bubblers in series between the cell and the carburetor, for always more safety.

So we had a few electrodes in parallel, in a good electrolyte, and straight DC from battery/alternator, with 15A of current; very good results in fuel saving on this local cars ; average 50% less petrol ! if long distance almost 70% savings (our record. It depend on the car, even if same model, result can be different…) and a good feeling of 'Pick-up' as we say here for more power under the pedal.

Water Electrolysis works very well for fuel saving !

BUT a lot of heat in the 'reactor', until the water boils, after only few minutes … and the water vapor going to the carburetor, electrolyte escaping, and Amperes increasing too much with the temperature … a lot of problems, simple parallel design with straight DC from alternator = no suitable. (we even find a designs called 'series-parallel' that gives more gas, all in the same cylinder, but heat still too much)

Then we were quite disappointed by this electrolyzers, a lot of Amps used, little gas produced, too much heat … and electronic was not our solution, we had no expertise, and because it also create a lot of heat at the transistors side, even for 10A, and need a huge & expensive heat sink and finally we didn't found extra gas production by using it…

How much we must thanks Tero.ranta from the E-gas forum, because his file on SERIES CELL gave us THE DESIGN THAT WORKS, and without electronic we get a lot more gas, and very less heat on the cell; with 7 cell in series we get to small Amps, so we made a 6 cells in series, and at 12.7V and 7A, it gave us 0,5L of gas per minute … 12.7 x7 = 88.9 Watts/ 30 Liters per hour = 3 Wh/L …

Series cells give a SUPER EFFICIENCY in gas production, straight from alternator DC !

So now we have a suitable electrolyzer (6 cells in series, distilled water with sodium hydroxide, straight DC) and it gives us important fuel savings and no problems of maintenance).

The first 2 weeks the starting current was 5A, going up to 10A when hot ; now we changed the electrolyte and we have 10A at starting, it seems that the cell is more efficient now !

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

--------------------------------------------- Return to the top

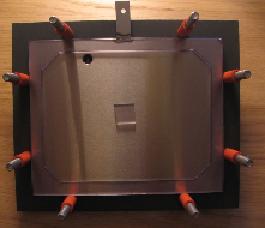

# - Pictures of standard parallel electrodes design :

# - Pictures abstract from the TERO.RENTA pdf file :

# - Some other pictures of Series-Cell design, from the web:

#>#># Click here for a LARGER and UPDATED version of this website #<#<#

--------------------------------------------- Return to the top

Electrolysis menu : CARS - LORRIES/GENERATORS - WELDING - HYSTORY and PATENTS - TRICKS - OWN REALIZATION

---------------------------------------------

Home -Introduction -Conclusion -Site Map - Links

Water Electrolysis Systems - Water Explosion Systems - Water Plasma Systems - Other Water Dissociation Systems - Other Systems